Menu

Close

PLTF – Pleated Bag House Filter

Get A Product Quote

Send us your information immediately with the product request form, and our sales team will reach you as soon as possible.

III PLTF – Pleated Bag House Filter

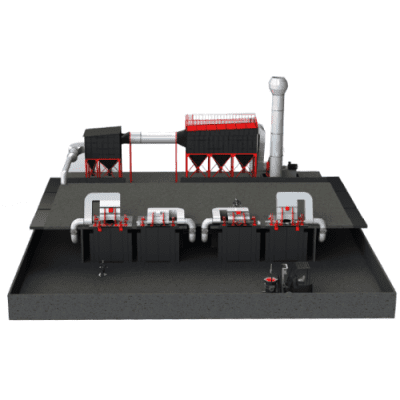

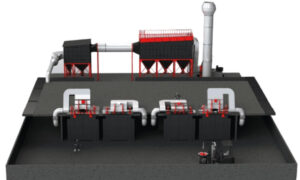

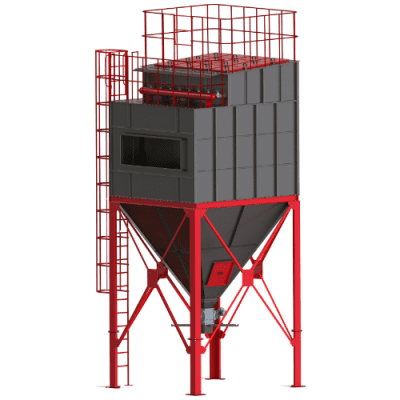

Bomaksan branded PLTF model Jet-Pulse Pleated Bag Filter Units are generally used in central system dust collection systems and fume extraction systems. Equipped with Jet-Pulse filter cleaning technology, which is among the indispensable parts of dedusting systems, the PLTF series has many advantages compared to traditional Jet-Pulse Baghouse Filter Units. The groundbreaking performance of the PLTF series is the result of Bomaksan’s engineers’ relentless efforts to improve their products and exceed customer expectations.

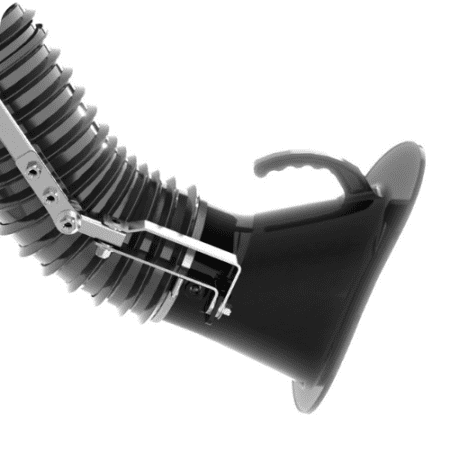

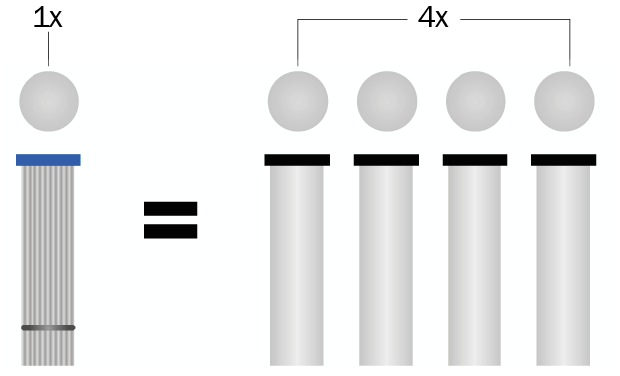

The most important advantage of the PLTF series is the high technology Pleated Bag Filters used in it. Pleated Bag Filters using polyMIGHT series non-woven spun-bond polyester technology can provide much higher filtration efficiency in a much more compact area compared to traditional bag filters.

In the image you see on the right, you can see the comparison of the traditional type jet-pulse bag filter unit (RIGHT) with the same capacity and Bomaksan branded PLTF model Jet-Pulse Pleated Bag Filter Unit (LEFT). PLTF model has much shorter lengths and much smaller footprints compared to bag filters of the same capacities.

ADVANTAGES OF PLEATED BAG FILTER UNITS

LESS ENERGY CONSUMPTION

- Pleated bag filters, which have the filtration area of 4 traditional type bag filters alone, consume much less compressed air in each cleaning period. In this way, they can work energy efficiently.

TAKE LESS SPACE

- It takes much less space in the same filtration area and allows you to allocate your precious factory area to your main production.

- It is the most suitable choice for companies with limited space.

BETTER FILTER LIFETIME

- PolyMIGHT spun-bond non-woven filters have a much longer filter life than traditional needle felt bag filters thanks to their surface filtration technologies.

- The long filter replacement period helps the factory to stop less for planned and unplanned outages and to increase your annual production capacity.

LESS FREQUENT & EASIER MAINTENANCE

- Pleated Bag Filters can be changed up to 6 times faster than traditional needle felt bag filters, due to their smaller number and easy attachment and detachment structure. This reduces your maintenance labor costs and downtime for maintenance. In this way, you can increase your annual production capacity.

| TRADITIONAL BAG FILTERS | PLEATED BAG FILTERS | |

| Filter Length | max. 8 mt. | max. 2 mt |

| Filtration Area | Less | 2-3 times the same size bag filter |

| Filter Lifetime | Acceptable | Perfect |

| Labour Cost (Installaiton / Maintenance) | High | Low |

| Leak / Wear | Time to time | Never |

| Emission Level | High | Low |

| Power Consumption | High | Low |

| Air Permability | Acceptable | Perfect |

| Pressure Drop | High | Low |

| Filter Cabinet Investment | High | Low |

HOW IT WORKS?

In Bomaksan branded PLTF model Jet-Pulse Pleated Bag Filter Units, access to the filters is from above by walking over the unit. In this way, the filter unit can fit into much narrower spaces.

PLTF model units have many input configurations. The inlet configuration is chosen to best suit your process and layout.

In PLTF model units, the dirty air hits a baffle plate at the dirty air inlet of the unit, which causes heavy particles to fall into the hopper with the help of gravity. In this way, the amount of dust reaching the filters is reduced. Reducing the dust load that filters have to filter means longer filter life and lower energy consumption. The baffle plate also prevents particles that may come to the filter unit and damage the filters in case of contact with the filters, from directly hitting the filter at a high speed.

Dust falling into the dust collecting hopper is transferred to the waste container (BIG-BAG, Barrel, etc.) with the help of dust discharge equipment (Cell Wheel, Screw Conveyor, etc.). Small particles that do not fall into the hopper are caught by the filters and prevented from passing into the cleanroom.

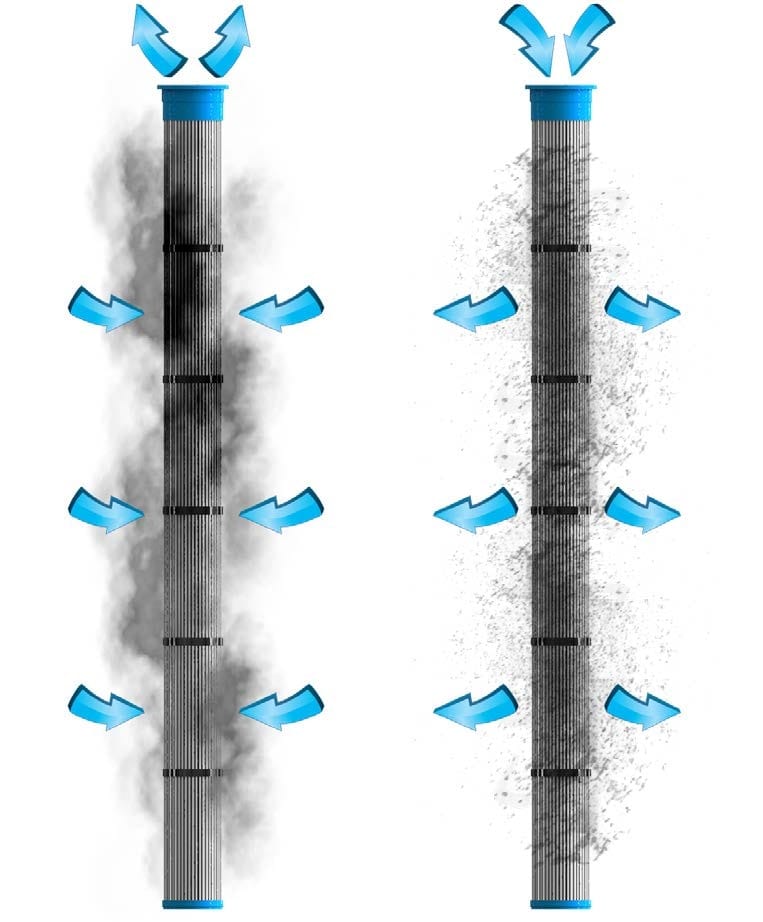

When a certain amount of dust accumulates on the filters, the pressure difference between the cleanroom and the dirty room starts to increase. When this pressure difference, which is monitored by the differential pressure sensors, exceeds a certain level, the automatic jet-pulse cleaning system is activated. Jet-Pulse cleaning system cleans the filters with compressed air by means of solenoid pulse valves.

III Catalogs

III Case Studies

WHY BOMAKSAN?

Always With You On Your Way Of Excellence

As Bomaksan, we are aware of your desire to do your job perfectly. Excellence means both producing the best quality product, meeting the quality and deadline expectations of your customers and even exceeding them, creating a healthy and safe working environment and producing without harming the environment.

This is why your investment in Dedusting Systems and Clean Air is actually a direct investment you make to perfect your business.

- Reliable Partner With 35 Years Of Experience!

- ECO-Friendly Engineering Solutions.

- Solutions For Safe Working Environments

- Durable & Sustainable Solutions

Consult Our Clean Air Experts For A More Perfect Production Experience

You can leave your contact information for our Clean Air Experts to provide you with the best support.

You can leave your contact information for our Clean Air Experts to provide you with the best support.

We will try to answer you as soon as possible. In some cases, the response time may be 48 hours.

As a company, we know what we want and since we go with those demands, our supply-demand balance is well maintained. In this respect, Bomaksan is a signature brand. We found answers to all of our problems with need-oriented solutions and alternative approaches. Our satisfaction is always at the top as they do not compromise on fast service and product quality!

Mert EryılmazNETZSCH - Technical Manager

A brand that always meets our expectations with its product quality. It has always been able to please us with the feedback and reactions towards our requests. Its place in the sector is always special with its engineering services and solution-oriented working principles!

Hakan KaplanTrakya Döküm - Assistant Business Engineer

Communication and service quality is at the highest level in Bomaksan. Always a reliable and responsible company!

Yasin TeberLindsay Corporation - Maintanence Technician

We would like to thank Bomaksan for not having any difficulties in communication with its timely service policy. We find answers to all our needs domestically, with the work they do globally!

Hüseyin MetinoğluAlbaksan A.Ş - Production Manager

Bomaksan succeeded in making a difference in the sector with its equipment and product quality. We have always received the best service with their quick reactions to our demands. Fast, reliable and solution oriented.

Orhan KuzubaşPulver Kimya

Bomaksan Dust Collection. It is an expert brand that has entered the production of Gas Treatment and Filtration devices and has managed to make a name for itself in the sector in a short time.

E-Newsletter Subscription

© 2017 - 2022 Bomaksan Industrial Air Filtration Systems. All Rights Reserved.