Menu

Close

Grinding

> Applications > Grinding

Are You Looking For A Solution?

Bomaksan Clean Air Experts are here for you. Fill the request form now, get one step closer to the solution.

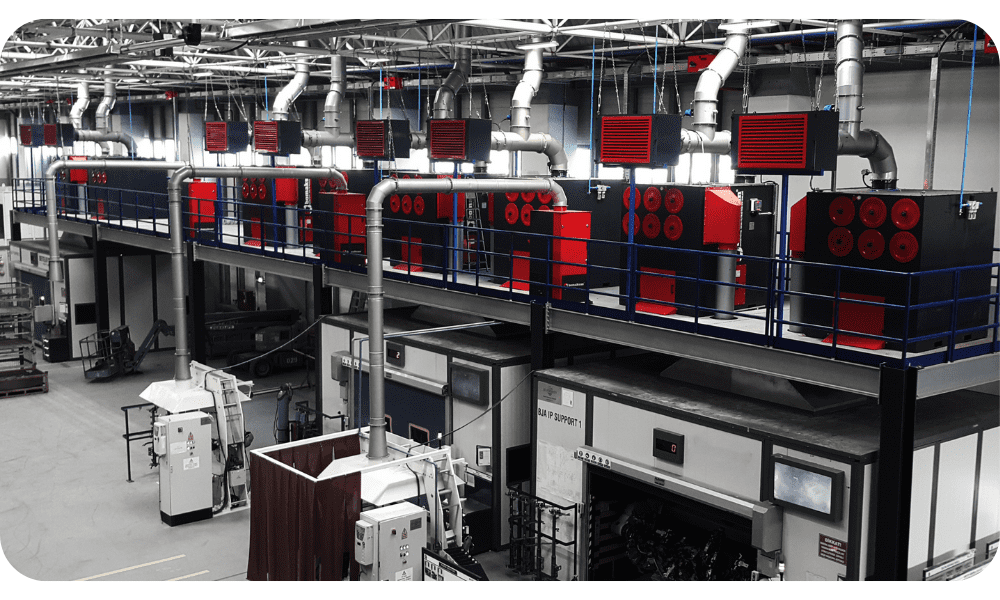

Reliable Partner for Grinding Processes

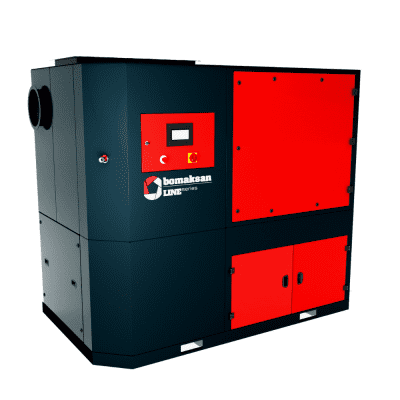

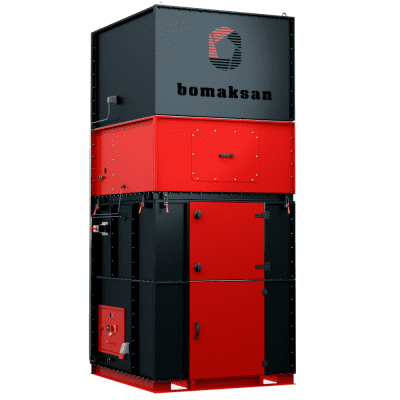

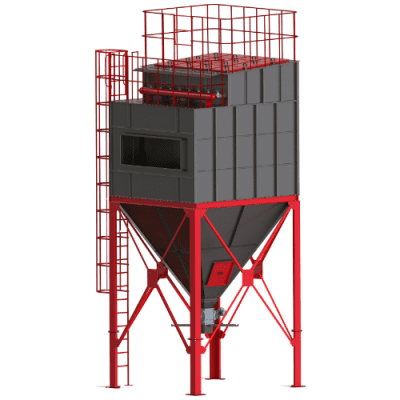

Bomaksan provides reliable and sustainable dust collector and fume extraction solutions.

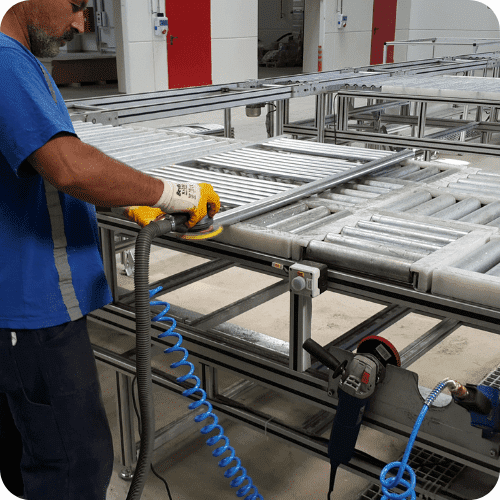

Grinding is a process in which various types of abrasive grains are used and various surface qualities are obtained to obtain a high quality and smooth surface. In order to process the surface with these abrasive grains, the abrasive grains are firmly attached to the rotating discs. With these abrasives, metal surfaces can be treated, as well as they can be applied on fibrous layers, paper or even fabric using different abrasive materials. Crushed diamonds called Aluminum Oxide, Silicon Carbide or Bort can be used as abrasive grains.

DUST AND SMOKE RELEASED DURING GRINDING

The ground materials and the particles released from these materials can consist of a wide variety of materials. For example; Materials such as ferrous and non-ferrous metals (aluminum, cast iron, steel, titanium, etc.), composite materials, rubber, rubber, and brake shoes are frequently encountered materials in grinding applications. Although the material and the coating on this material determine the characteristics of the dust and smoke released in the grinding application, the structure and properties of the disc used during grinding also play a role in the formation of this characteristic.

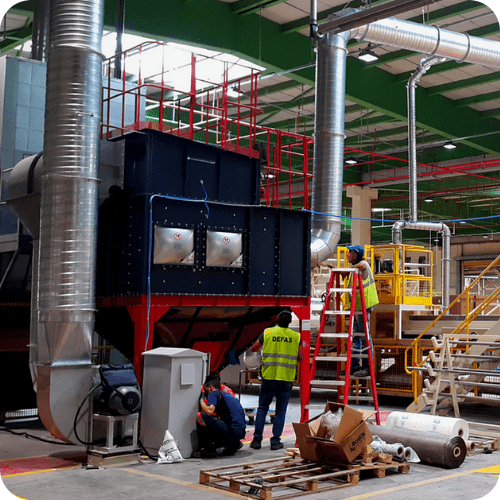

Dust and smoke released during grinding application are generally abrasive and may have a risk of fire and explosion depending on the material being grinded. Again, depending on the material being grinded and the grinding disc used, it may also be able to be clumped. Bomaksan engineers make specific product selections for your grinding application. EX-PROOF filter units can be manufactured with ATEX certified equipment for applications with risk of explosion, and customer-specific studies can be carried out on the precautions to be taken against all kinds of fire and explosion risks.

In order to create an efficient and healthy working environment, it is necessary to remove and filter the smoke and dust caused by all these materials from the breathing air of the employees in a healthy and effective way. Factories that do not increase precautions for work accidents and occupational diseases, thanks to the increased awareness and awareness in recent years, both experience a shortage of qualified personnel and face lawsuits with serious consequences in the long term. Companies that take precautions against work accidents and occupational diseases at the highest level have increased productivity thanks to employee satisfaction as well as providing a sustainable production center.

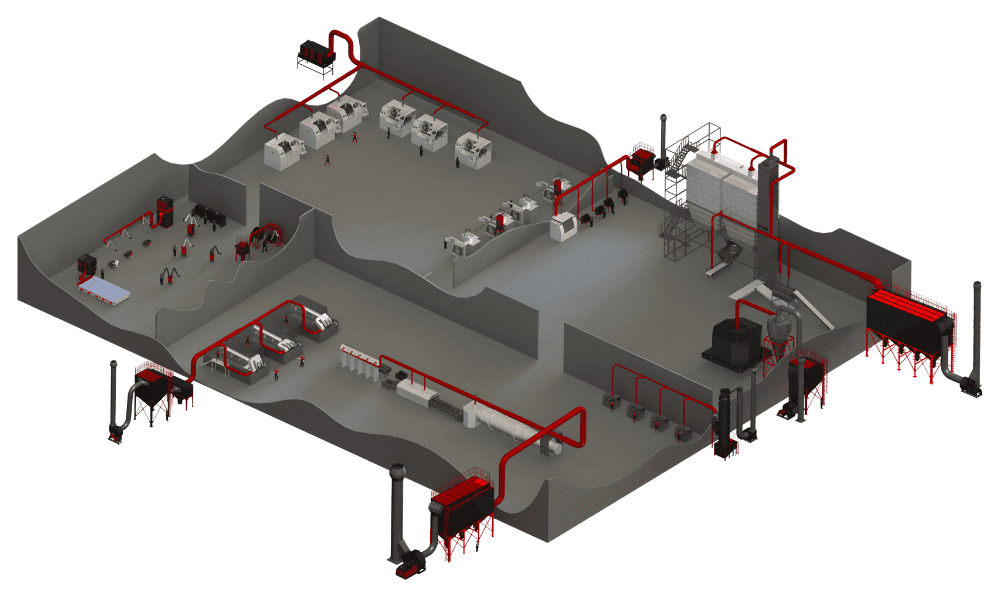

WHAT SHOULD BE CONSIDERED WHEN DESIGNING THE SUCTION SYSTEM?

The main points to be considered while designing the ventilation system for the suction of dust and smoke released during the grinding application are as follows;

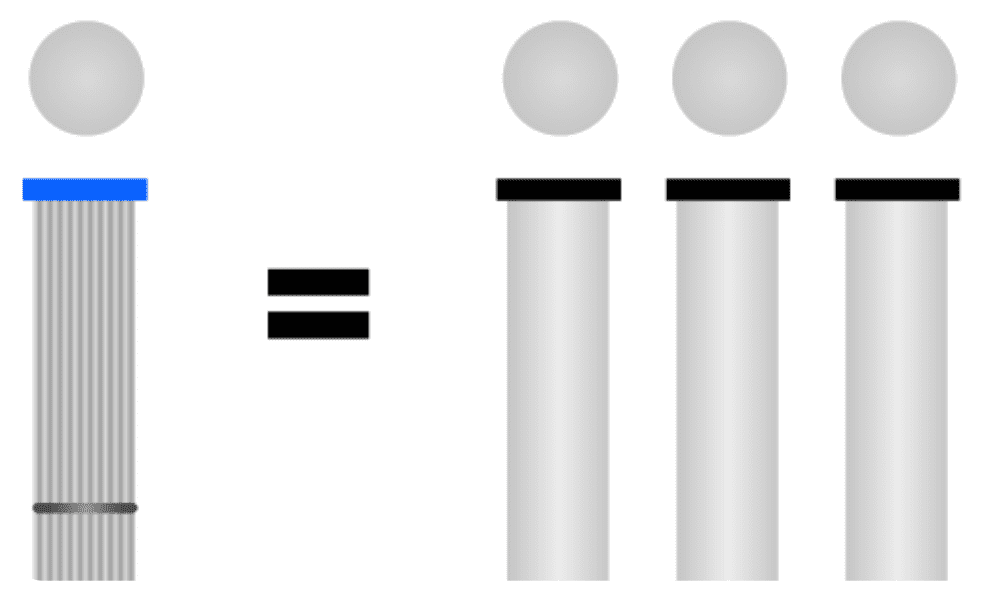

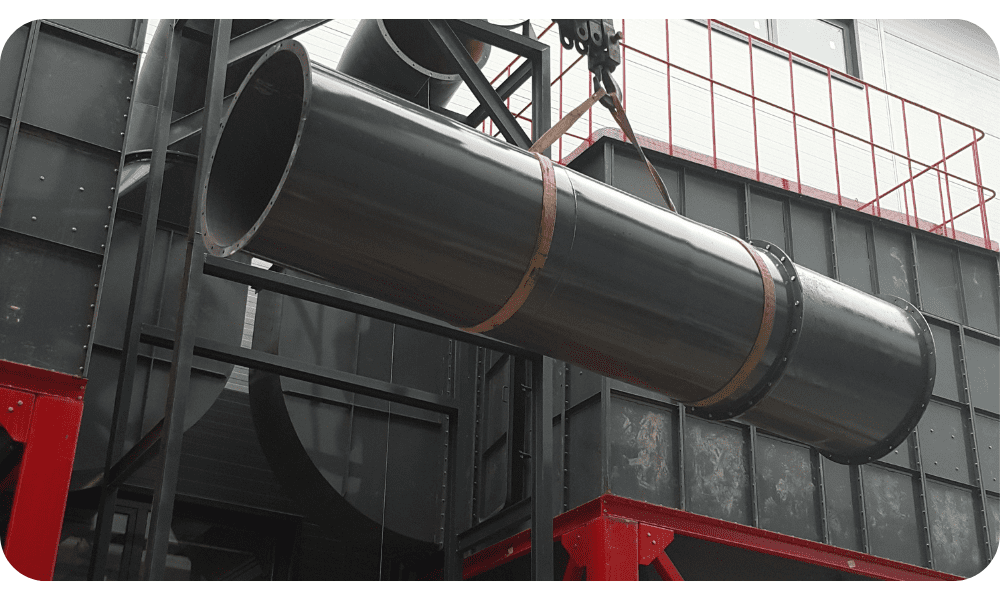

Corrosive dust resistant steel channels

Spiral clamped galvanized piping is not suitable for this application because the dust released during grinding is abrasive. Systems made with spiral clamped pipes are starting to cause problems in a short time.

Precautions Against Fire Risk

Grinding dust and smoke have a risk of fire depending on the type of material being grinded. In cases where this risk occurs, measures should be taken to ensure that spark reaches the filter, and precautions should be taken to minimize the damage in case of a possible fire.

Precautions Against Explosion Risk

Depending on the type of material being grinded, grinding dust and fumes have the risk of explosion. In cases where this risk occurs, precautions for sparking to the filter as well as measures to minimize the damage in the event of a possible explosion should be taken.

Corrosive dust resistant steel channels

Spiral clamped galvanized piping is not suitable for this application because the dust released during grinding is abrasive. Systems made with spiral clamped pipes are starting to cause problems in a short time.

Precautions Against Fire Risk

Grinding dust and smoke have a risk of fire depending on the type of material being grinded. In cases where this risk occurs, measures should be taken to ensure that spark reaches the filter, and precautions should be taken to minimize the damage in case of a possible fire.

Precautions Against Explosion Risk

Depending on the type of material being grinded, grinding dust and fumes have the risk of explosion. In cases where this risk occurs, precautions for sparking to the filter as well as measures to minimize the damage in the event of a possible explosion should be taken.

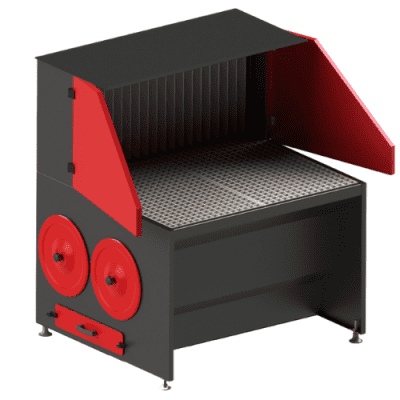

Design for Reducing Electricity Consumption

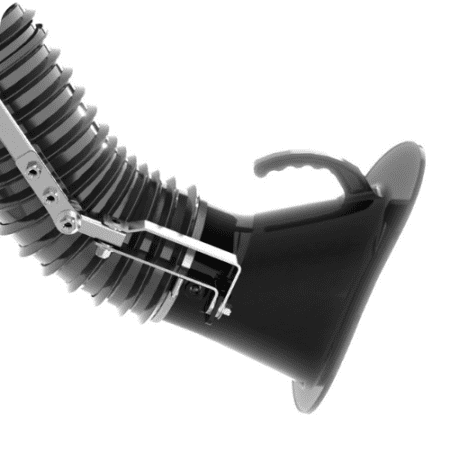

There can be different grinding applications in each industry. While some companies grind small pieces, some companies grind much larger pieces. However, regardless of the application, the system designer must take the dust and fume extraction from the closest possible point in order to reduce the electricity consumption and the initial investment cost. In addition to being close to the suction point, the fact that the suction area is closed as much as possible will reduce the size of the device in the initial investment and minimize electricity consumption. Bomaksan Engineers will assist you in such system designs.

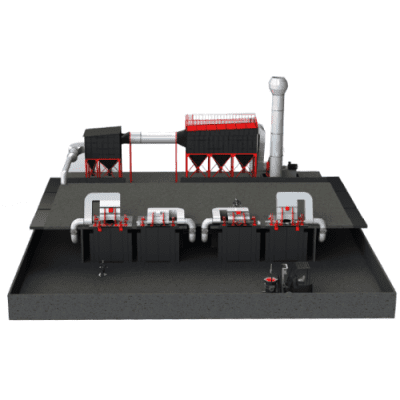

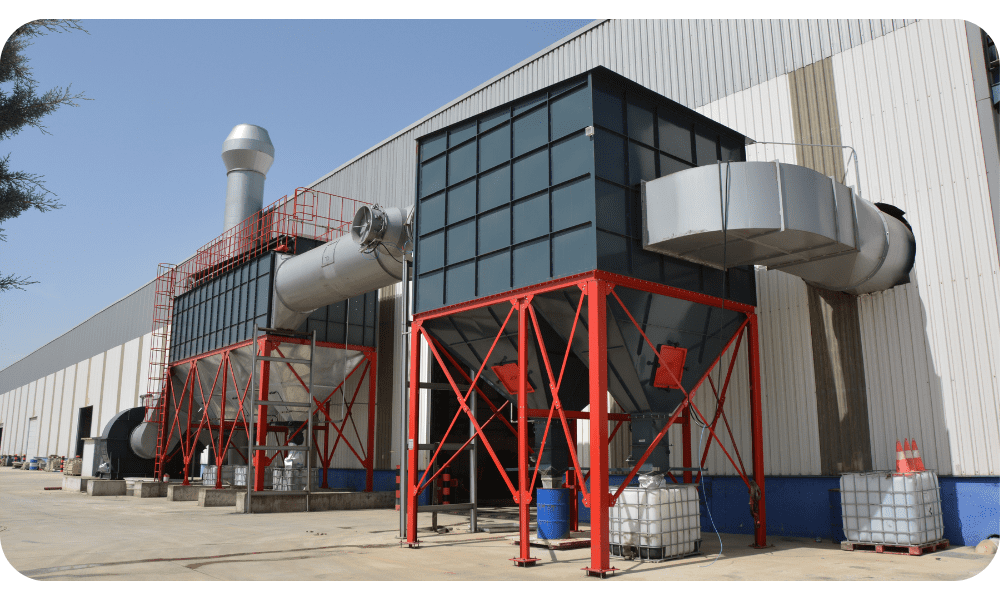

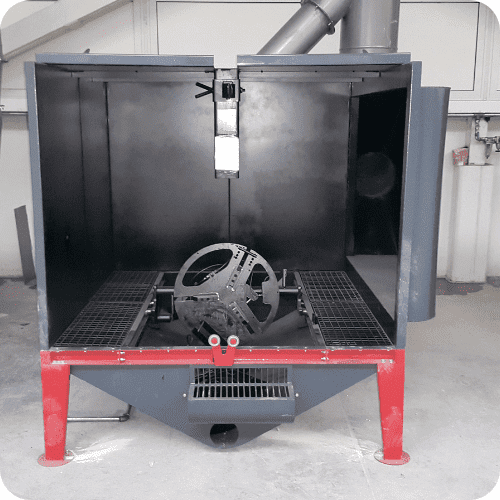

CHOOSING THE RIGHT FILTER UNIT

Dust collection systems used for the suction and filtration of dust and fumes during grinding application are critical for the effective collection and filtration of submicron particles (less than 1 µm). ASHRAE (American Society of Heating, Refrigerating and Air Conditioning Engineers) uses the Minimum Efficiency Rating Value (MERV) criterion to determine the filter efficiency and capacity of particles within a certain size range. Minimum MERV 15 filters should be used for the filtration of dust and smoke released during the grinding process. In the filtration of highly harmful particles such as Chromium (Stainless Steel), Copper and Manganese, a filter efficiency of MERV 16 and above is required.

Dust collection systems used for the suction and filtration of dust and fumes during grinding application are critical for the effective collection and filtration of submicron particles (less than 1 µm). ASHRAE (American Society of Heating, Refrigerating and Air Conditioning Engineers) uses the Minimum Efficiency Rating Value (MERV) criterion to determine the filter efficiency and capacity of particles within a certain size range. Minimum MERV 15 filters should be used for the filtration of dust and smoke released during the grinding process. In the filtration of highly harmful particles such as Chromium (Stainless Steel), Copper and Manganese, a filter efficiency of MERV 16 and above is required.

The area in which the extraction unit is kept) plays a critical role in efficiently filtering the fumes released during the grinding application. In processes where the filter media cannot be selected correctly, undesirable consequences such as frequent clogging of the filters, high electricity consumption, frequent pauses of the grinding process may occur. Therefore, high quality filter media must be used.

In addition to the filter media, a good Jet-Pulse dust collector should have a highly efficient cleaning system, easy maintenance and universal spare parts. Bomaksan brand filter units are superior to other brands thanks to these superior features.

Bomaksan is the first and only local company in Turkey to receive a grant from TUBITAK by conducting R&D studies in order to increase the efficiency of Jet-Pulse cleaning systems in the field of Jet-Pulse Dust Collection.

WHY BOMAKSAN?

Always With You On Your Way Of Excellence

As Bomaksan, we are aware of your desire to do your job perfectly. Excellence means both producing the best quality product, meeting the quality and deadline expectations of your customers and even exceeding them, creating a healthy and safe working environment and producing without harming the environment.

This is why your investment in Dedusting Systems and Clean Air is actually a direct investment you make to perfect your business.

- Reliable Partner With 35 Years Of Experience!

- ECO-Friendly Engineering Solutions.

- Solutions For Safe Working Environments

- Durable & Sustainable Solutions

Consult Our Clean Air Experts For A More Perfect Production Experience

You can leave your contact information for our Clean Air Experts to provide you with the best support.

You can leave your contact information for our Clean Air Experts to provide you with the best support.

We will try to answer you as soon as possible. In some cases, the response time may be 48 hours.

As a company, we know what we want and since we go with those demands, our supply-demand balance is well maintained. In this respect, Bomaksan is a signature brand. We found answers to all of our problems with need-oriented solutions and alternative approaches. Our satisfaction is always at the top as they do not compromise on fast service and product quality!

Mert EryılmazNETZSCH - Technical Manager

A brand that always meets our expectations with its product quality. It has always been able to please us with the feedback and reactions towards our requests. Its place in the sector is always special with its engineering services and solution-oriented working principles!

Hakan KaplanTrakya Döküm - Assistant Business Engineer

Communication and service quality is at the highest level in Bomaksan. Always a reliable and responsible company!

Yasin TeberLindsay Corporation - Maintanence Technician

We would like to thank Bomaksan for not having any difficulties in communication with its timely service policy. We find answers to all our needs domestically, with the work they do globally!

Hüseyin MetinoğluAlbaksan A.Ş - Production Manager

Bomaksan succeeded in making a difference in the sector with its equipment and product quality. We have always received the best service with their quick reactions to our demands. Fast, reliable and solution oriented.

Orhan KuzubaşPulver Kimya

Bomaksan Dust Collection. It is an expert brand that has entered the production of Gas Treatment and Filtration devices and has managed to make a name for itself in the sector in a short time.

E-Newsletter Subscription

© 2017 - 2022 Bomaksan Industrial Air Filtration Systems. All Rights Reserved.