Menu

Close

Hot-Dip Galvanizing

> Applications > Hot-Dip Galvanizing

Are You Looking For A Solution?

Bomaksan Clean Air Experts are here for you. Fill the request form now, get one step closer to the solution.

Videos

Case Studies

Table of Contents

Reliable Partner for Hot-Dip Galvanizing Processes

Bomaksan provides reliable and sustainable dust collector and fume extraction solutions.

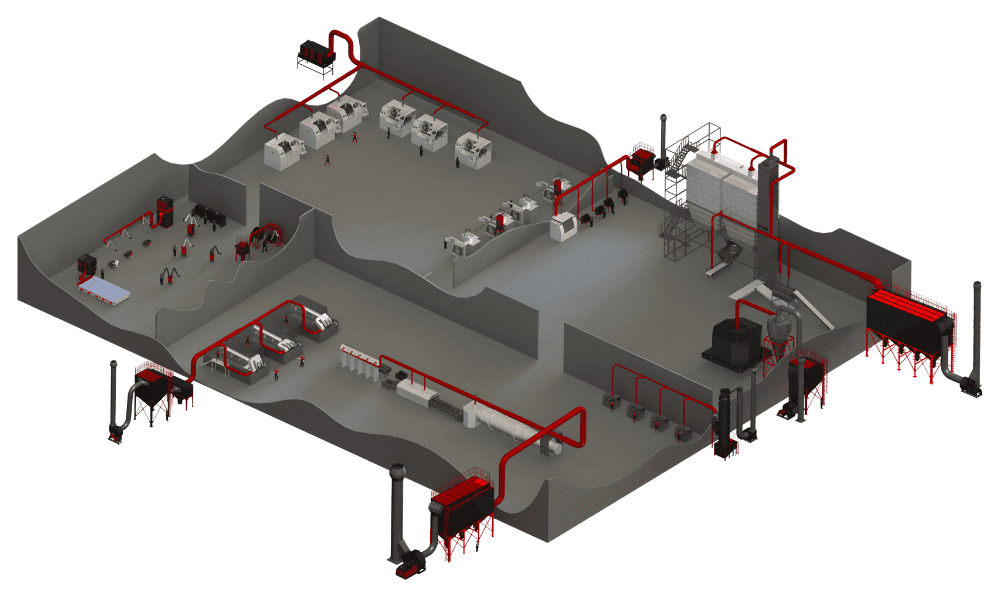

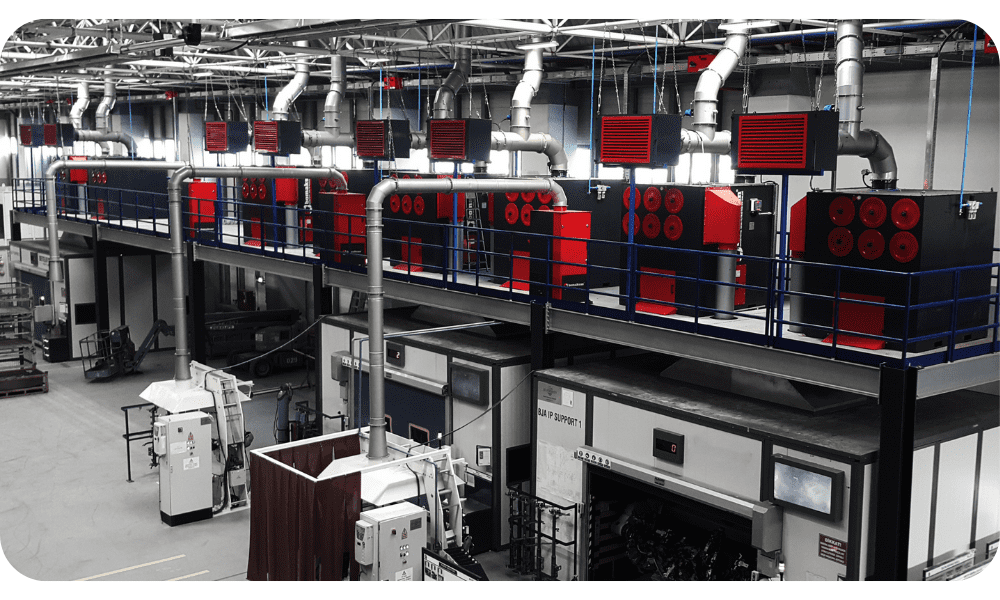

Bomaksan Industrial Air Filtration Systems, which is one of the first companies to come to mind when it comes to filtration in Galvanized Coating plants, is preferred by dozens of companies thanks to its more than 30 years of manufacturing and design experience. Bomaksan, with its expert engineers and technicians, provides you with the services of technical specification preparation, manufacturing and assembly of filters during the establishment of Galvanized Coating facilities or the improvement of an existing dust collection system. Bomaksan is with you whenever you need it, thanks to its expert field teams in after-sales maintenance and usage support.

Galvanized Immersion Fume Extraction and Filtration

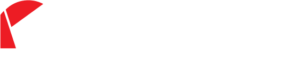

The application of Galvanized Coating, which is referred to as Hot Dip Galvanizing in the literature, is generally used to apply zinc, nickel etc. It is the process of coating with substances. In this process, after the surface to be coated is subjected to various processes, the coating process is performed by coming to the zinc pool. A toxic fumes are released due to the chemical reactions that start during this coating / dipping process. Inhaling this smoke is very harmful for human health. In addition, it reduces the efficiency of your working environment by reducing the air quality of your factory.

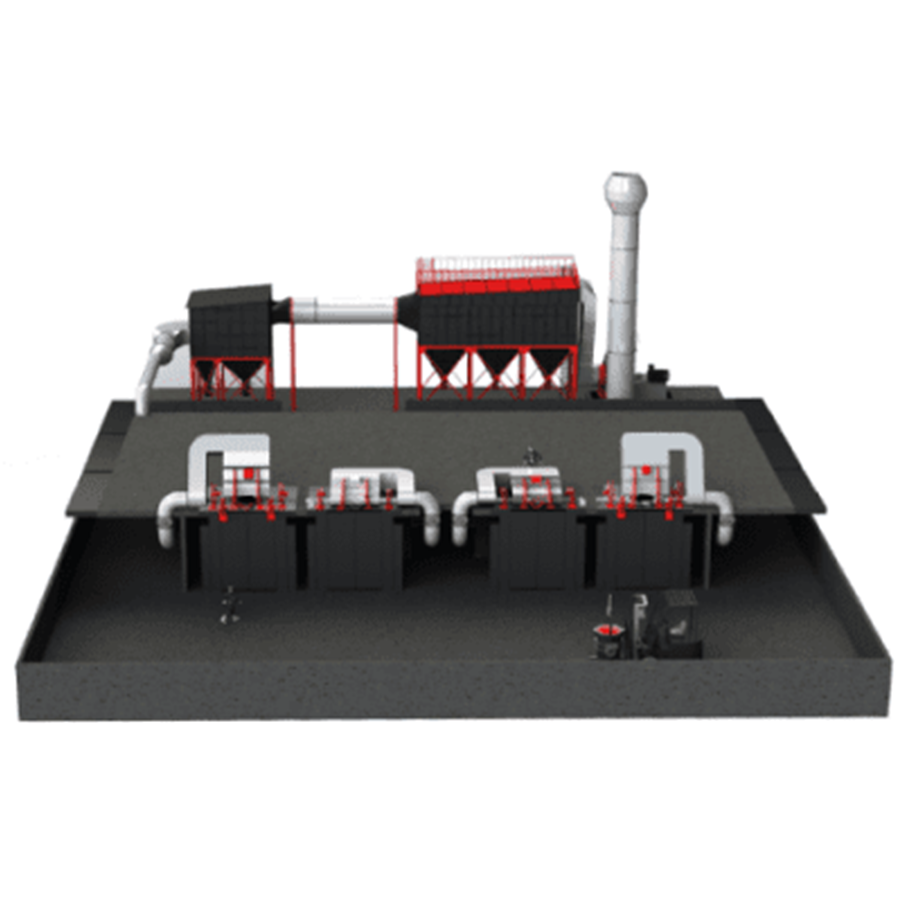

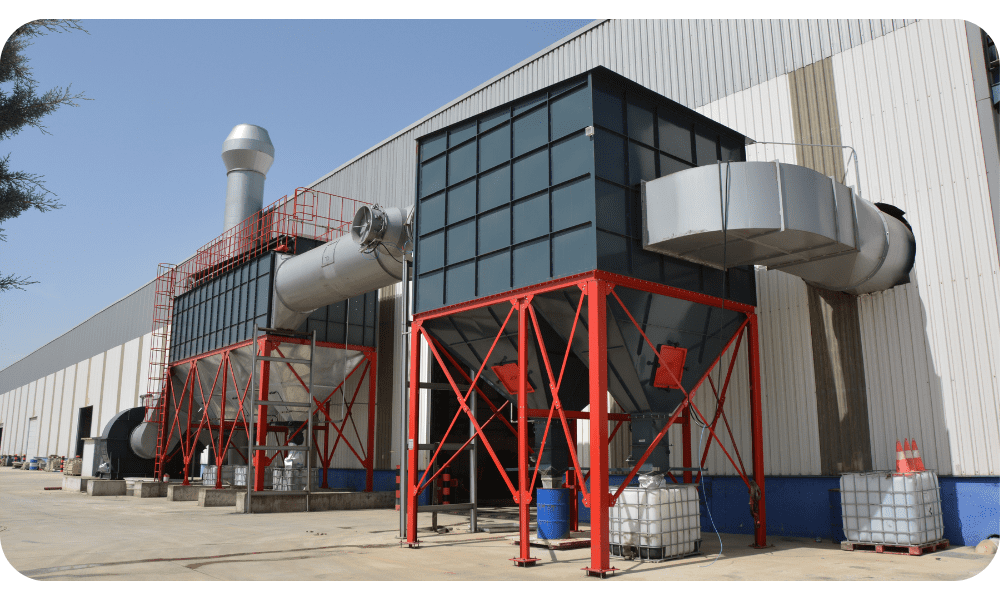

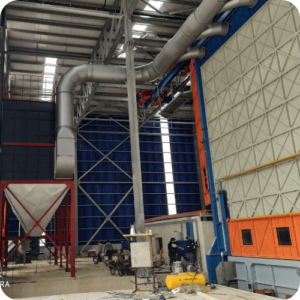

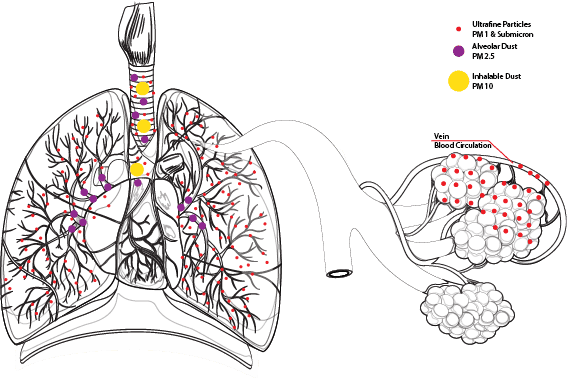

Bomaksan Industrial Air Filtration Systems offers the most effective solution to this smoke problem that occurs in Galvanized Dip facilities. The zinc pool, also known as the hot dip pool, is covered by an enclosure (encology, enclosure). Suction is carried out from inside this closed area. The most important reason for closing is to create the lowest flow rate that can absorb the released smoke. The smoke absorbed from here is transferred to Jet-Pulse filters. It can be released into the atmosphere by passing through these filters with automatic cleaning system. Bomaksan brand filters always guarantee to meet the emission values of both the Ministry of Labor and the Ministry of Environment.

The most economical solutions in ventilation and dust collection techniques are properly designed systems. The most important issue in these systems is the accurate calculation of critical pressures and air flow rates by competent engineers. Bomaksan engineers work meticulously on the project designed for your factory to create the lowest possible air flow rates. Low air flow means low investment and maintenance costs. Bomaksan offers the right solution for you with its experienced engineers and expert team. Bomaksan, aware of the fact that cheap filters are not economical filters, work for you to create the most economical solution for your factory.

SUMM SUCTION AND FILTRATION FROM GALVANIZED POOL

In order for a suction system that extracts fumes from a deep-immersed galvanizing pool or a dust collection system to work effectively, all components that make up the system must be selected and designed correctly. Otherwise, the system could be as powerful and effective as the weakest link of the components. Think of an antique 1940 vehicle. Even if we install the engine of a state-of-the-art sports car on this car, the maximum speed it can achieve depends on the vehicle’s wheels, clutch system, suspension and driver. As in this example, if your dust collection and fume extraction system does not have a properly designed and positioned suction hood and duct project, your dust collection unit cannot perform enough, even if it is the latest technology.

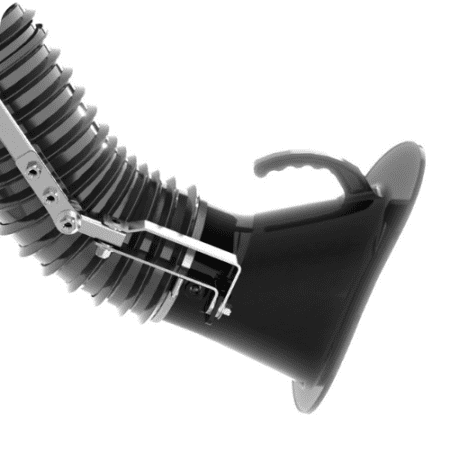

SELECTION OF SUCTION HOOD

The suction hood located in the zinc pool, also known as the hot dip pool, is a very important component for a fume extraction system that works efficiently and protects employees. A properly designed suction hood cannot effectively capture this harmful fumes emitted from the zinc pool and cannot prevent employees from being exposed to this toxic smoke. Again, a suction hood that is not positioned by experts will not work efficiently. For a system that can be created with much lower investment and operating costs, you may have to pay very high amounts and, moreover, constantly face the negative effects of this wrong solution on electricity bills.

In deep-dip galvanizing plants, the zinc pools are covered by an enclosure (encology, closure). Suction is carried out from inside this closed area. The most important reason for closing is to create the lowest flow rate that can absorb the released smoke. The smoke absorbed from here is transferred to Jet-Pulse filters. It can be released into the atmosphere by passing through these filters with automatic cleaning system. Bomaksan brand filters always guarantee to meet the emission values of both the Ministry of Labor and the Ministry of Environment.

For more detailed information on this subject, “How to Evaluate Dust Collection System Performance?” You can review our article.

After choosing the right designed and positioned suction hood, it is time to choose the right channeling project and application.

CHANNEL PROJECT

The ducting project directly determines the energy consumption of the suction fan. The suction fan should be designed to overcome all pressure losses on the system. Pressure losses are created by the suction hood, ducts, filter unit and the fan itself. When the duct project is done by experts, the suction fan will consume energy at the optimum level and prevent you from wasting energy. For detailed information, you can review our “Correct Channel Project Makes Money” article.

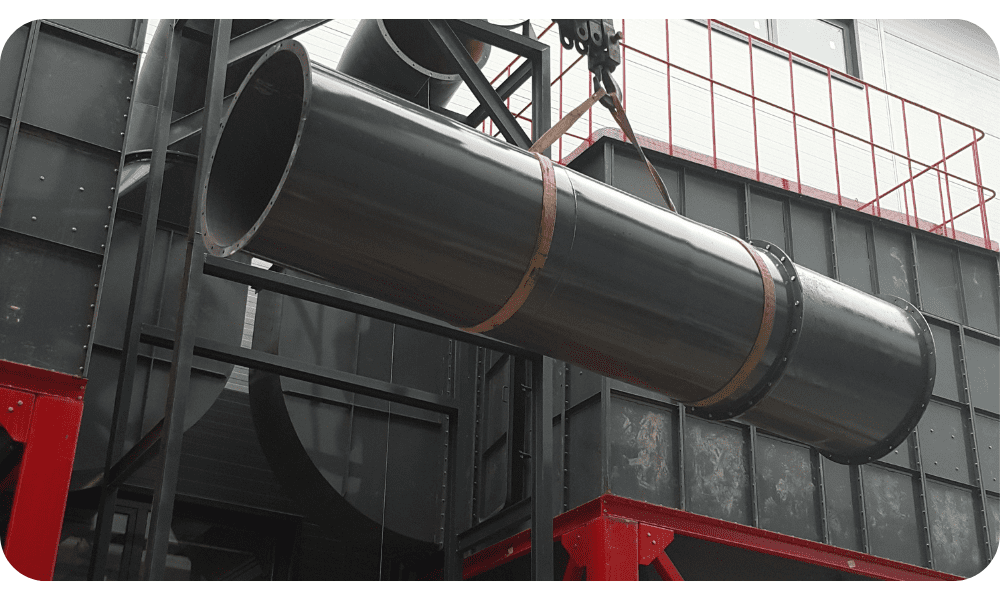

When making a channel project, 2 issues are very important; duct material and dust / smoke transport rate. As in many dust collection projects, the use of spiral clamped galvanized pipes is not recommended for the suction of the smoke from the zinc pools in deep-dipping facilities. Since the smoke coming out of the zinc pool is highly corrosive, steel channels of appropriate thickness are used, which are preferred in many dust collection projects. Choosing the correct dust / fume transport rate in the suction of smoke and dusts released in deep-dip galvanizing plants is very critical for duct sizing. Dust / smoke transport speed is selected according to the size of the zinc pool and the intensity of use. You can get support from Bomaksan clean air experts.

DUST COLLECTING UNIT

When you prepare the design and positioning of the suction hood and the duct project, you also determine the air flow capacity and pressure loss in front of the filter required for an effective and efficient suction. These 2 values are indispensable for choosing the right dust collector unit, but they are not enough to choose the most suitable dust collector unit for your process. When choosing a dust collector unit, you should determine the following criteria;

1. What is the usage density of the galvanized pool?

2. What is the total surface area of the products that are dipped in the pool at one time?

3. Will you place the dust collector indoors or outdoors?

4. Will the filtered air be discharged to the atmosphere or indoors?

By contacting our Bomaksan Clean Air Experts, you can get detailed information about the issues you should pay attention to while determining these criteria.

Filter media (the area where dust and fumes are kept in the dust extraction unit) plays a critical role in the efficient filtering of fumes from the zinc pool in deep-dip galvanizing plants. In processes where the filter media cannot be selected correctly, undesirable consequences such as frequent clogging of the filters, high electricity consumption, frequent pauses of the galvanized immersion process may occur. Therefore, high quality filter media must be used.

In addition to the filter media, a good Jet-Pulse dust collector should have a highly efficient cleaning system, easy maintenance and universal spare parts. Bomaksan brand filter units are superior to other brands thanks to these superior features.

Bomaksan is the first and only local company in Turkey to receive a grant from TUBITAK by conducting R&D studies in order to increase the efficiency of Jet-Pulse cleaning systems in the field of Jet-Pulse Dust Collection.

WHY BOMAKSAN?

Always With You On Your Way Of Excellence

As Bomaksan, we are aware of your desire to do your job perfectly. Excellence means both producing the best quality product, meeting the quality and deadline expectations of your customers and even exceeding them, creating a healthy and safe working environment and producing without harming the environment.

This is why your investment in Dedusting Systems and Clean Air is actually a direct investment you make to perfect your business.

- Reliable Partner With 35 Years Of Experience!

- ECO-Friendly Engineering Solutions.

- Solutions For Safe Working Environments

- Durable & Sustainable Solutions

Consult Our Clean Air Experts For A More Perfect Production Experience

You can leave your contact information for our Clean Air Experts to provide you with the best support.

You can leave your contact information for our Clean Air Experts to provide you with the best support.

We will try to answer you as soon as possible. In some cases, the response time may be 48 hours.

As a company, we know what we want and since we go with those demands, our supply-demand balance is well maintained. In this respect, Bomaksan is a signature brand. We found answers to all of our problems with need-oriented solutions and alternative approaches. Our satisfaction is always at the top as they do not compromise on fast service and product quality!

Mert EryılmazNETZSCH - Technical Manager

A brand that always meets our expectations with its product quality. It has always been able to please us with the feedback and reactions towards our requests. Its place in the sector is always special with its engineering services and solution-oriented working principles!

Hakan KaplanTrakya Döküm - Assistant Business Engineer

Communication and service quality is at the highest level in Bomaksan. Always a reliable and responsible company!

Yasin TeberLindsay Corporation - Maintanence Technician

We would like to thank Bomaksan for not having any difficulties in communication with its timely service policy. We find answers to all our needs domestically, with the work they do globally!

Hüseyin MetinoğluAlbaksan A.Ş - Production Manager

Bomaksan succeeded in making a difference in the sector with its equipment and product quality. We have always received the best service with their quick reactions to our demands. Fast, reliable and solution oriented.

Orhan KuzubaşPulver Kimya

Bomaksan Dust Collection. It is an expert brand that has entered the production of Gas Treatment and Filtration devices and has managed to make a name for itself in the sector in a short time.

E-Newsletter Subscription

© 2017 - 2022 Bomaksan Industrial Air Filtration Systems. All Rights Reserved.