What Is Welding Fume? Why It Should Be Filtered?

The most popular method of welding today is mild steel welding, which is important for every industry that uses welding in its production process. Latest

When designing dust collection systems, the processes in which pollution is released should be carefully examined. These processes can sometimes be a direct part of the production process, sometimes dust, fume and oil mist particles are released as a result of production and cause pollution. Regardless of the type of process, determining the location of the filter units is very important for system design. Filter unit placement can be in several different ways.

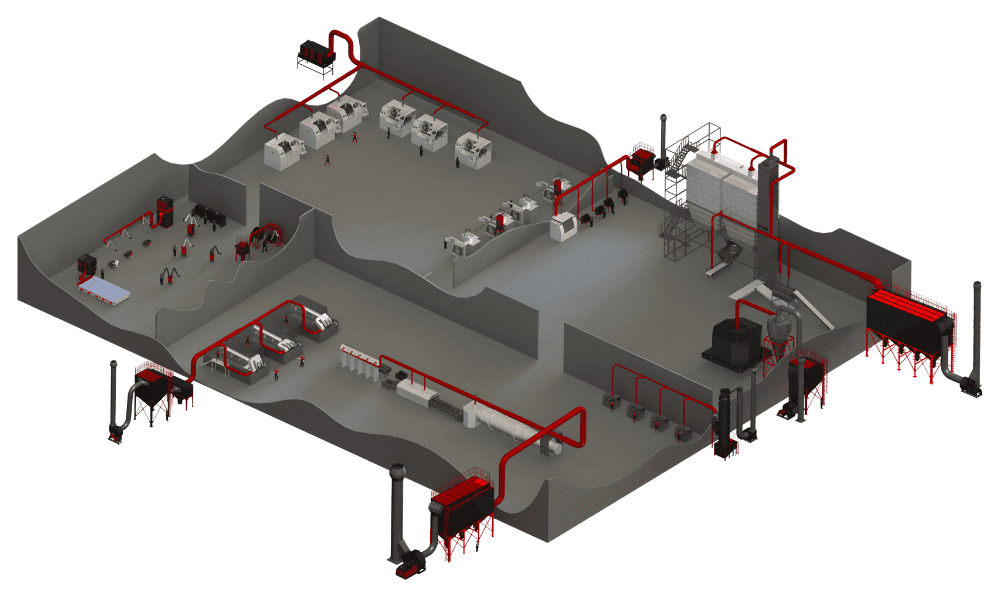

1. Central Dust Collection System

The central dust collection system is the name given to the transmission of polluted air collected from multiple pollution sources with different hoods to a single filter unit. In these systems, the filter unit can placed either indoor or outdoor. In this title, we will talk about the strategy by which the filter unit is positioned outside.

There are some advantages and disadvantages of locating the central dust collection system outdoors. These advantages and disadvantages may vary according to the needs of the business. For example, while a situation may be an advantage for some systems, it may be a disadvantage for other systems. Therefore, filter unit positioning should be evaluated separately for each system.

For example, in bulk material handling facilities, dust and pollution are generated in many different areas. These are crusher, conveyor transport lines, mixers, bag filling, and unloading places. These areas are fields that run in series, and when one stops, all systems stop due to the nature of the process. For this reason, the pollution from all these areas can be filtered in a single central dust collector unit. Space constraints are often a problem in these facilities, and placing the unit outdoors can also save a significant amount of space.

Another advantage of this positioning strategy is that dust and fume can be collected from many pollution sources with a single filter unit. This means fewer filter units to maintain and monitor. The initial investment cost of these systems is generally lower.

Besides all the benefits mentioned above, a central unit placed outdoors has some disadvantages.

Although the investment cost of the filter unit in central filter units is low, there is a serious ducting cost. Also, when this system is installed outside, the duct lengths will increase and the cost of the system is higher. In systems with many and long ducts, the total pressure loss that the suction fan must overcome is naturally high. This means higher electricity consumption. These costs are relatively lower when the central filter unit is positioned indoors.

Another disadvantage of the central filter unit, regardless of whether it is placed indoors or outdoors, is that all processes must be stopped when a fault occurs in the filter unit in systems that do not operate in series (not working in conjunction with each other). In serial systems, this is not a problem, because when any process stops, with or without a central dust collection system, other processes have to stop. However, since systems operating in parallel are not connected to each other, when one process stops, the other can continue production.

Another disadvantage of the central filter unit operation in parallel systems is that even if one of the systems stops for another reason, air extraction will continue from there. This will cause unnecessary energy consumption.

In summary, when choosing a central filter unit, it is necessary to analyze the system to be installed with a dust collection system very well. In this way, the most advantageous solution can be produced for the business owner.

NOTE: Care should be taken not to mix different types of pollutants in central units. Otherwise, unwanted results may be encountered.

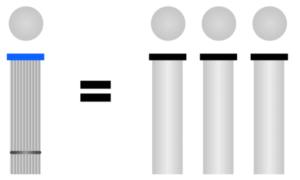

2. Station-Based Filter Unit Layout

A station-based dust collection system can be preferred in processes where the central dust collection system loses its advantages. The first issue that attracts the attention of business owners in station-based dust collection systems is the increasing number of filter units, fans, and motors. Business owners may initially think this means increased operating costs and higher investment costs, but this is often not true. Except for some special cases, station-based filter unit layouts provide both lower investment costs and lower operating costs. Factors causing this situation;

– Using smaller diameter and fewer ducts (lower initial investment cost)

– Installation in a much shorter time (lower initial investment cost)

– Lower energy consumption due to shorter duct lines (lower operating costs)

Case Studies

The most popular method of welding today is mild steel welding, which is important for every industry that uses welding in its production process. Latest

Whether it is industrial production or not, there are moments in every sector where the planned activities do not take place within the desired time

Project designers and process owners often focus on filtering devices when designing or purchasing a dust collection system. Yet another area they focus on is

© 2017 - 2022 Bomaksan Industrial Air Filtration Systems. All Rights Reserved.