What Is Welding Fume? Why It Should Be Filtered?

The most popular method of welding today is mild steel welding, which is important for every industry that uses welding in its production process. Latest

What is Dust Leak?

Dust leakage problem, which is one of the most common problems in dust collection and filtration systems, is the leakage of the dust and particles out of the clean air chamber. In case of dust leakage, unwanted dust comes out from the fan discharge. This dust pollutes the environment when the fan discharges it to the atmosphere, and it pollutes the production facility when it is discharged into the indoor air. For this reason, necessary measures should be taken to prevent this problem and to be intervened quickly in case of an incident.

One point should be noted here. It is not possible for dust collection systems to work with 100% filtration efficiency. Dust collecting units guarantee an emission of max 20 mg/Nm³ in most cases. Although this amount can be pulled down to 5 mg/Nm³ in filter units using new technologies and designed accordingly, many existing technologies are designed according to the emission value of 20 or even 30 mg / Nm³. In other words, a dust collection system with a capacity of 50,000 m³ / h can discharge 50,000 m³ * 20 mg / Nm³ = 1,000,000 mg = 1 kg of dust per hour from the fan. This means 8 kg of dust in a system that works 8 hours a day. It is important not to confuse dust leakage with the normal emission value accepted by law.

There is no dust leakage in properly working dust collection systems. Dust leakage is an indication of a defective situation and requires intervention. Below, we will discuss the steps to be taken in case of dust leakage.

1. Determining Dust Leakage

Dust leaks in the dust collecting unit are usually visible from the fan discharge. It is important to visually check the fan discharge at regular intervals and in many cases, it will allow the problem to be resolved before it grows. For this reason, it is recommended to add a visual observation of the fan shots of dust collecting units to your maintenance routines.

Dust leakage problems with your dust collection and filtration unit can be caused by any of the following:

1 A. Damaged ( torn, etc.) Filter Media

The part that holds the dust and cleans the air in the filter units is the filter media. (Also called filter paper, filter bag, etc.). At the same time, filter media are one of the most important components in a dust collection system that create resistance in the airflow. Air likes to go the easiest way it can find (ie where the resistance is least), just like an electric current. When there is damage on the filter media, the dust-laden dirty air will prefer to glide through the holes where it encounters lower resistance rather than moving through the filter media where it encounters high resistance. This situation causes dust leakage in the filter unit.

1.B. Bent or Damaged Filter Flanges (Bag cage, cartridge filter flanges etc.)

Filter elements are connected to a sheet plate called a filter plate, which separates the dirty room and the cleanroom in the unit. Connection elements that allow the filters to be tightly attached to this sheet plate are called filter flanges. If the flange of a filter element is damaged, it cannot be tightly attached to the filter plate. For this reason, dust-laden dirty air will leak from this space and cause dust leakage.

1.C Faulty Filter Unit Design

If the sheet metal plates called filter plates are not strong enough, they will deflect with the weight of the filters. In this case, filter flanges, which are filter fittings and are responsible for sealing, may not grasp the filter plate correctly and may create gaps. In this case, dust-laden dirty air leaks from this space and causes dust leakage.

1.D. Incorrect installation of the filters

Dust leaks may occur if filter elements are not properly mounted inside the filter units. Situations, where the filter flanges do not properly grip the filter plate, are one of the most common causes of dust leaks.

1.E. A bag filter that fell out of its cage

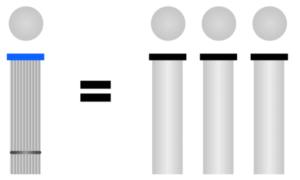

In baghouse dust collection systems, support elements called cages are used. The most important function of these cages is to ensure that the bag filters can stand in a rigid structure and to help the bag filters to maintain their physical form. Cage and bag filters can be connected to each other in different ways. In some cases, this connection loosens over time and the bag filter slips out of the cage and falls into the dust hopper. In this case, dust leakage occurs.

1.F. Perforation of dust conveying ducts or filter body due to wear

Special design arrangements are required for the collection and filtering of highly abrasive dust. If these arrangements are not made, abrasive dust may cause dust leakage by piercing the ducts it passes through and even the filter unit body. This dust leak cannot be observed from the fan discharge, but can be easily observed from the filter unit.

Solving the Problem

Whether bag filter, cartridge filter, or pleated bag filter, the most common cause of dust leakage is damaged filter media. For this reason, checking the physical forms of the filters should be the first step to be taken when there is a dust leakage problem. If the physical form of the filters is damaged and/or the filter media is damaged, it is recommended to replace the entire filter set in the filter unit. (If the whole set was changed 1-2 months ago, you can only replace the damaged filters)

If there is no noticeable deformation in the filter media and the forms appear properly, you can plan your next step by answering the following questions:

– How long have the filters been installed and/or is it time to change the filter?

– What is the value read on the differential pressure sensor on the filter unit and has it changed recently?

– Is Filter maintenance caps loose, misaligned, or damaged?

– Are the filter maintenance cover seals torn or badly tightened?

– Examine the hopper of the filter units. Check if there any dust in them? If not, find out where those dust is.

– Are the filters fitted correctly?

– If bag filters have flexible ring flanges, do they fit properly in the cage?

– Does the excess material at the end of bag filters ensure proper sealing?

– Is any of the bag filter snap ring flange bent? Is the physical form of those snap rings OK?

– Are all filter fittings (Filter flanges) in place and properly tightened?

– Is there any dust on the clean side of bag filters, cartridge filters, or pleated bag filters? If there is, it helps you identify which filter is leaking.

– Does the dust leak increase when the jet-pulse system is activated? If not, the problem may not be in the filters. (When the compressed air hits the filters, the amount of dust leakage from there will increase as the fittings and filter media will stretch a little)

Visually inspecting damaged or physically deformed filters can give an idea about the reasons for dust leakage. For example, are there any signs of wear on the filter media? Are the filter media showing signs of scorching or freezing due to temperature? Any burns, brittleness, etc. on the filter media. Are there any signs of chemical deformation? Findings obtained as a result of such visual examinations may prevent this situation from happening again.

Before changing the filter after a dust leak occurs, you should make sure that the dust and particles in the cleanroom and the fan are thoroughly cleaned. Otherwise, even if there is no leakage in the filter unit, there will be some dust leakage from the stack during the first start up, and you will look for a ghost problem that does not exist.

Dust leaks are one of the most frequently encountered problems in dust collection systems and the causes are easy to identify and remedy. If dust leaks continue to occur, you can contact the Bomaksan service and maintenance team.

Bomaksan service and maintenance team provides the necessary service and maintenance services for any brand

Case Studies

The most popular method of welding today is mild steel welding, which is important for every industry that uses welding in its production process. Latest

Many industrial companies are seeking information on how to evaluate the performance of working dust collection systems. Many researches and articles which process owner refers

Whether it is industrial production or not, there are moments in every sector where the planned activities do not take place within the desired time

© 2017 - 2022 Bomaksan Industrial Air Filtration Systems. All Rights Reserved.