Menu

Close

PKF Series

Get A Product Quote

Send us your information immediately with the product request form, and our sales team will reach you as soon as possible.

III PKF Series

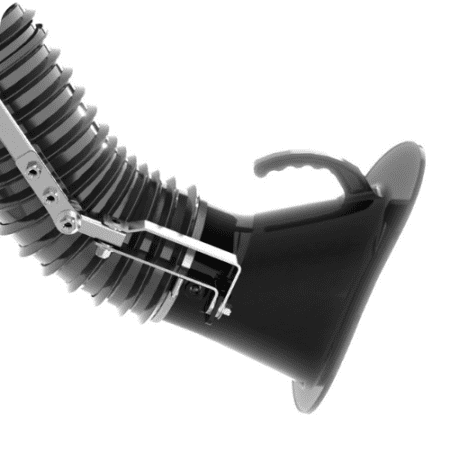

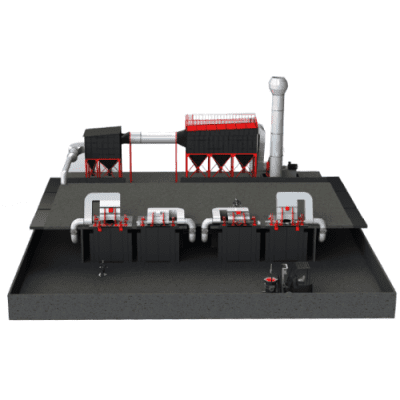

The PKF series Jet-Pulse modular cartridge filter unit, which emerged as a result of Bomaksan’s desire to exceed customer needs and expectations and endless efforts to develop a product with excellent quality, makes a difference with its high performance and modular design that defy even the most demanding dust loads.

Our team designed the PKF series devices as a device that can grow modularly with your future needs and investments, and designed the unit modularly, considering your transportation costs. This way, you do not have to purchase special transport services when transporting a PKF series Jet-Pulse modular cartridge filter unit. Bomaksan branded PKF series Jet-Pulse modular cartridge dust and fume extraction units are dust collectors with superior technology and energy efficiency, which can be used in applications with medium-high dust load and fume extraction applications.

PKF series Jet-Pulse modular cartridge dust and fume extractors are the appropriate choices between 2,500 m³ / h – 100,000 m³ / h air capacities. These units show high performance in CNC Plasma / Laser Cutting devices, welding fume extraction, static paint booths, sandblasting booths, filtering the dust generated during grinding application, and many other applications. Thanks to its modular design, when your suction capacity needs to increase with your new investments, your old filtration system investment will not go to waste.

In some cases, PKF series Jet-Pulse modular cartridge filter units may not be the right solution. Situations such as the absorption of oily fumes are some of these. In these and similar cases, you can consult your Bomaksan sales representative and get the most accurate solution at the most affordable prices.

III Catalogs

WHY BOMAKSAN?

Always With You On Your Way Of Excellence

As Bomaksan, we are aware of your desire to do your job perfectly. Excellence means both producing the best quality product, meeting the quality and deadline expectations of your customers and even exceeding them, creating a healthy and safe working environment and producing without harming the environment.

This is why your investment in Dedusting Systems and Clean Air is actually a direct investment you make to perfect your business.

- Reliable Partner With 35 Years Of Experience!

- ECO-Friendly Engineering Solutions.

- Solutions For Safe Working Environments

- Durable & Sustainable Solutions

Consult Our Clean Air Experts For A More Perfect Production Experience

You can leave your contact information for our Clean Air Experts to provide you with the best support.

You can leave your contact information for our Clean Air Experts to provide you with the best support.

We will try to answer you as soon as possible. In some cases, the response time may be 48 hours.

As a company, we know what we want and since we go with those demands, our supply-demand balance is well maintained. In this respect, Bomaksan is a signature brand. We found answers to all of our problems with need-oriented solutions and alternative approaches. Our satisfaction is always at the top as they do not compromise on fast service and product quality!

Mert EryılmazNETZSCH - Technical Manager

A brand that always meets our expectations with its product quality. It has always been able to please us with the feedback and reactions towards our requests. Its place in the sector is always special with its engineering services and solution-oriented working principles!

Hakan KaplanTrakya Döküm - Assistant Business Engineer

Communication and service quality is at the highest level in Bomaksan. Always a reliable and responsible company!

Yasin TeberLindsay Corporation - Maintanence Technician

We would like to thank Bomaksan for not having any difficulties in communication with its timely service policy. We find answers to all our needs domestically, with the work they do globally!

Hüseyin MetinoğluAlbaksan A.Ş - Production Manager

Bomaksan succeeded in making a difference in the sector with its equipment and product quality. We have always received the best service with their quick reactions to our demands. Fast, reliable and solution oriented.

Orhan KuzubaşPulver Kimya

Bomaksan Dust Collection. It is an expert brand that has entered the production of Gas Treatment and Filtration devices and has managed to make a name for itself in the sector in a short time.

E-Newsletter Subscription

© 2017 - 2022 Bomaksan Industrial Air Filtration Systems. All Rights Reserved.