Menu

Close

DALGAKIRAN

DALGAKIRAN

Process Date

2019

Application

Metalworking

Location

Dilovası, Türkiye

www.dalgakiran.com

III Problem

DALGAKIRAN Compressor, one of the leading companies of the Turkish and World compressor sector, had demands for the collection and filtering of dust, smoke and oil vapor released from the welding process, oxygen cutting process and CNC processing benches in the newly built Dilovası production facility without spreading to the environment and working environment. Believing in the importance of a dust-free and smoke-free production process for healthy and safe working environments and a sustainable world, DALGAKIRAN was looking for a company specialized in dedusting and filtration.

III Solution

As Bomaksan, we worked with TEMAS engineering firm, which has produced solutions for various installation and ventilation processes of DALGAKIRAN company in this project. Bomaksan provided support with special solutions in order to realize the project prepared by TEMAS Engineering and to provide solutions with long-lasting and efficient filter units.

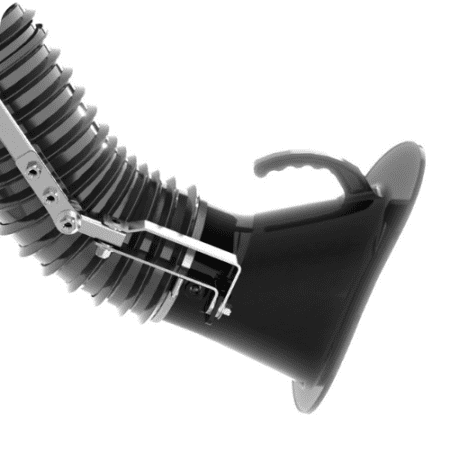

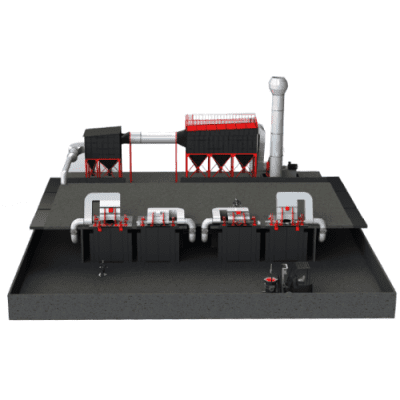

AKROBAT PLUS acrobat arms, BKM model work tables and LINE model Jet-Pulse Compact Panel Filter Unit were used together for welding fume extraction and filtration. Dust and smoke collected with AKROBAT PLUS model acrobat arms and BKM model work tables were collected in LINE model filter unit with smoke carrying pipes. The air cleaned in LINE filter units with H13 class high filtration efficiency is returned to the working environment, resulting in serious heat savings, especially in winter.

Bomaksan engineers were asked for a new suction table in the Oxygen Cutting area, as their bench is old and not suitable for suction. The most important feature of this suction tray was that the oxygen cutting was specially designed for the harsh working environment and that it could provide high suction power even at low capacities thanks to its modular structure. By connecting a LINE model jet-pulse compact panel filter unit to this counter, high efficiency suction and filtration was achieved.

On the other hand, a mixed solution was offered in CNC lathes and processing benches due to the settlement conditions. Groupable benches were grouped to YBF model filter units, and non-groupable benches were individually connected to YBF PRO model filter units, effectively solving the oil mist problem.

Previous slide

Next slide

WHY BOMAKSAN?

Always With You On Your Way Of Excellence

As Bomaksan, we are aware of your desire to do your job perfectly. Excellence means both producing the best quality product, meeting the quality and deadline expectations of your customers and even exceeding them, creating a healthy and safe working environment and producing without harming the environment.

This is why your investment in Dedusting Systems and Clean Air is actually a direct investment you make to perfect your business.

- Reliable Partner With 35 Years Of Experience!

- ECO-Friendly Engineering Solutions.

- Solutions For Safe Working Environments

- Durable & Sustainable Solutions

Consult Our Clean Air Experts For A More Perfect Production Experience

You can leave your contact information for our Clean Air Experts to provide you with the best support.

You can leave your contact information for our Clean Air Experts to provide you with the best support.

We will try to answer you as soon as possible. In some cases, the response time may be 48 hours.

As a company, we know what we want and since we go with those demands, our supply-demand balance is well maintained. In this respect, Bomaksan is a signature brand. We found answers to all of our problems with need-oriented solutions and alternative approaches. Our satisfaction is always at the top as they do not compromise on fast service and product quality!

Mert EryılmazNETZSCH - Technical Manager

A brand that always meets our expectations with its product quality. It has always been able to please us with the feedback and reactions towards our requests. Its place in the sector is always special with its engineering services and solution-oriented working principles!

Hakan KaplanTrakya Döküm - Assistant Business Engineer

Communication and service quality is at the highest level in Bomaksan. Always a reliable and responsible company!

Yasin TeberLindsay Corporation - Maintanence Technician

We would like to thank Bomaksan for not having any difficulties in communication with its timely service policy. We find answers to all our needs domestically, with the work they do globally!

Hüseyin MetinoğluAlbaksan A.Ş - Production Manager

Bomaksan succeeded in making a difference in the sector with its equipment and product quality. We have always received the best service with their quick reactions to our demands. Fast, reliable and solution oriented.

Orhan KuzubaşPulver Kimya

Bomaksan Dust Collection. It is an expert brand that has entered the production of Gas Treatment and Filtration devices and has managed to make a name for itself in the sector in a short time.

E-Newsletter Subscription

© 2017 - 2022 Bomaksan Industrial Air Filtration Systems. All Rights Reserved.