Menu

Close

Machining

> Applications > Machining

III Oil Mist Filtration for CNC Machining and Metalworking Applications

Protect your employees, machines, and production quality with effective oil mist filtration systems. Improve indoor air quality and comply with health & safety regulations.

During CNC machining, milling, lathing, and grinding operations, oil mist is generated as a result of coolant or lubricant evaporation caused by high temperatures. Without proper control, this mist spreads across the workspace, reducing air quality, damaging sensitive machine components, and posing health risks to operators.

CNC machining oil mist extraction and metalworking mist filtration are essential to ensure a clean, safe, and compliant work environment. Whether it’s a machine tool mist collector, or dedicated oil mist filtration for lathes, milling machines, or grinding machines, source-capture solutions significantly reduce airborne contamination.

Companies that implement efficient mist collection systems not only comply with occupational safety regulations but also benefit from higher productivity, reduced maintenance costs, and a healthier workforce. Investing in oil mist control is no longer optional—it’s a vital part of sustainable manufacturing.

III Why Oil Mist Filtration Matters in Industrial Settings?

In today’s industrial environments—especially in CNC machining, milling, lathing, and grinding applications—the use of coolants and lubricants leads to the formation of oil mist. This airborne mist contains fine droplets that can travel long distances, contaminate machinery, and degrade indoor air quality. Without an effective oil mist filtration system, facilities face not only serious health and safety issues but also increased maintenance costs and reduced equipment lifespan.

Implementing reliable oil mist extraction solutions is no longer a luxury—it’s essential. Whether through centralized filtration units or machine tool mist collectors, controlling oil mist is a key factor for safe, compliant, and sustainable production

The Hidden Danger of Oil Mist Exposure

Oil mist may seem invisible, but its impact is undeniable. In metalworking and CNC machining environments, workers are often unknowingly exposed to fine aerosolized particles generated by high-speed operations and hot surfaces. These particles can bypass basic ventilation systems and settle deep in the lungs, potentially leading to respiratory diseases and chronic conditions over time.

Beyond health, oil mist settles on floors and equipment, creating slippery surfaces and increasing the risk of workplace accidents. That’s why metalworking mist filtration and CNC machining oil mist extraction are critical for protecting your team and ensuring long-term workplace safety.

Impact on Health, Safety, and Productivity

Uncontrolled oil mist doesn’t just pose health risks—it directly affects productivity and operational efficiency. Accumulated mist on sensors, control panels, or moving machine parts leads to unscheduled downtimes, costly repairs, and poor machining accuracy. Additionally, poor air quality can result in higher employee turnover, increased sick leave, and lower morale.

By investing in high-efficiency systems such as oil mist filtration for lathes, milling machines, and grinding machines, companies benefit from improved machine reliability, cleaner working conditions, and higher operator satisfaction. A clean air environment is not just a regulatory requirement—it’s a competitive advantage.

III Industries and Applications Requiring Oil Mist Extraction

In modern manufacturing environments, oil mist extraction is not optional—it’s a necessity. Wherever metalworking fluids are used at high speeds and temperatures, oil mist is produced. This affects not only indoor air quality but also machine performance, safety, and legal compliance.

Key industries such as automotive, aerospace, defense, metal fabrication, foundry operations, and machinery manufacturing all rely on efficient oil mist filtration systems. These systems prevent the spread of hazardous mist and ensure that employees work in a clean, productive environment.

Below are the most common applications that require advanced oil mist extraction:

CNC Machining Centers

CNC machining oil mist extraction is crucial for keeping high-speed automated systems operating reliably. The combination of tight enclosures, rapid spindle speeds, and coolant use creates a high concentration of airborne mist inside and around the machines. Without proper machine-mounted mist collectors, oil residue builds up on components and optical sensors, causing frequent faults and maintenance issues.

Installing compact oil mist filtration systems on CNC machining centers helps reduce downtime, prevent contamination, and maintain consistent production quality.

Lathes and Turning Machines

Turning operations with neat oils or emulsions create a fine mist as the tool makes constant contact with rotating parts. This mist can spread far beyond the lathe’s enclosure, affecting operators and nearby workstations.

Oil mist filtration for lathes ensures that harmful particles are captured at the source before they disperse. A properly designed lathe oil mist extraction system improves worker safety, prevents equipment corrosion, and reduces the need for constant cleaning.

Milling and Drilling Equipment

During milling and drilling, the friction between cutting tools and the workpiece rapidly heats the metal, vaporizing lubricants and generating oil mist. When left unchecked, this mist can reduce tool life, fog up safety windows, and create slip hazards on floors.

Using oil mist filtration for milling machines and drilling setups ensures clean air and improved visibility, which is critical for operator control and production accuracy. Integration with centralized or modular mist collection systems provides scalable protection for multi-machine workshops.

Grinding Machines

Oil mist filtration for grinding machines is often overlooked but essential. The fine particle size of mist produced during grinding allows it to linger in the air for long periods. Combined with metallic dust, this creates a highly hazardous environment for workers and electronics alike.

Deploying metalworking mist filtration systems in grinding stations drastically reduces airborne pollutants and protects both the process and the people. In high-precision grinding operations, clean air directly translates into tighter tolerances and higher product quality

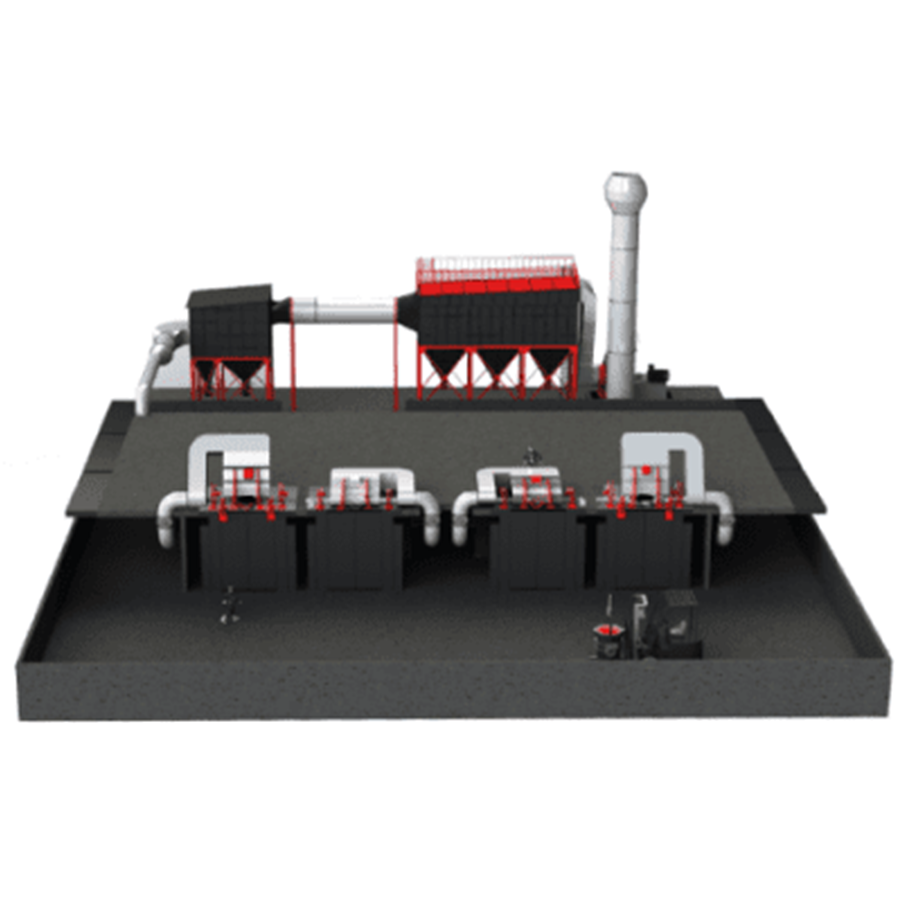

III Bomaksan’s Tailored Oil Mist Filtration Solutions

At Bomaksan, we understand that oil mist challenges vary across industries and machines. That’s why we offer custom-engineered oil mist extraction systems designed to meet the specific needs of your facility—whether it’s CNC machining, milling, turning, or grinding.

Our advanced product line combines high-efficiency filtration, compact design, and compatibility with various production setups. From machine-mounted mist collectors to modular centralized units, Bomaksan ensures effective, scalable solutions that outperform off-the-shelf systems.

High-Efficiency Multi-Stage Filtration

Bomaksan oil mist collectors feature multi-stage filtration technology, optimized to remove both visible mist and submicron particles. The process starts with pre-separation, followed by coalescing filters, and—if needed—HEPA filtration to ensure ultra-clean air. This configuration is ideal for metalworking mist filtration, where precision and air purity are critical.

Each filter stage is engineered for long service life, high efficiency, and low pressure drop—ensuring minimal energy consumption with maximum performance.

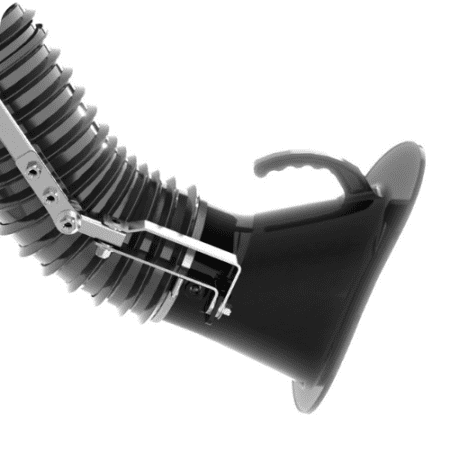

Compact & Machine-Mounted Systems

Space-saving is critical in today’s manufacturing floors. Bomaksan’s compact oil mist collectors can be directly mounted on CNC machining centers, lathes, or drilling machines, eliminating the need for ducting or large-scale setups. These plug & play units are perfect for machine tool mist collection, especially in retrofit applications or when flexibility is required.

Our compact systems reduce installation time, increase mobility, and maintain consistent extraction directly at the pollution source.

III Benefits of Bomaksan Oil Mist Systems

Investing in Bomaksan means more than just clean air. Our systems contribute to a safer workplace, lower maintenance burden, and greater operational efficiency. Below are some of the key benefits that set us apart:

Improved Indoor Air Quality

By effectively capturing and filtering oil mist at the source, Bomaksan systems significantly improve indoor air quality. This creates a healthier environment for employees, reduces odors, and enhances visibility on the shop floor. Cleaner air also prevents long-term respiratory risks, contributing to higher workforce satisfaction and productivity.

Reduced Maintenance and Downtime

Oil mist buildup in and around machinery leads to frequent breakdowns, unplanned maintenance, and repetitive cleaning. Over time, this can cause issues such as contamination of sensitive components, corrosion, and safety hazards due to slippery surfaces. Bomaksan’s CNC oil mist extraction systems are designed to tackle these challenges by capturing and filtering airborne oil mist directly at the source. This minimizes contamination, keeps machine enclosures clean and dry, and extends the life of critical components. With fewer cleaning cycles and reduced downtime, operations run more smoothly, maintenance costs drop, and overall efficiency improves significantly.

Compliance with International Standards

Bomaksan oil mist filtration units are manufactured in compliance with international quality and safety standards such as ISO 9001, CE, and applicable workplace safety directives. By reducing employee exposure and maintaining air cleanliness levels, our solutions help you meet—and exceed—regulatory requirements in global markets.

III Example Applications

III Related Products

III Related Brochures

Are You Looking For A Solution?

Bomaksan Clean Air Experts are here for you. Fill the request form now, get one step closer to the solution.

WHY BOMAKSAN?

Always With You On Your Way Of Excellence

As Bomaksan, we are aware of your desire to do your job perfectly. Excellence means both producing the best quality product, meeting the quality and deadline expectations of your customers and even exceeding them, creating a healthy and safe working environment and producing without harming the environment.

This is why your investment in Dedusting Systems and Clean Air is actually a direct investment you make to perfect your business.

- Reliable Partner With 35 Years Of Experience!

- ECO-Friendly Engineering Solutions.

- Solutions For Safe Working Environments

- Durable & Sustainable Solutions

Consult Our Clean Air Experts For A More Perfect Production Experience

You can leave your contact information for our Clean Air Experts to provide you with the best support.

You can leave your contact information for our Clean Air Experts to provide you with the best support.

We will try to answer you as soon as possible. In some cases, the response time may be 48 hours.

Bomaksan Dust Collection. It is an expert brand that has entered the production of Gas Treatment and Filtration devices and has managed to make a name for itself in the sector in a short time.

E-Newsletter Subscription

© 2017 - 2022 Bomaksan Industrial Air Filtration Systems. All Rights Reserved.