Menu

Close

ECOG

III Sample Installations

Get A Product Quote

Send us your information immediately with the product request form, and our sales team will reach you as soon as possible.

III ECOG

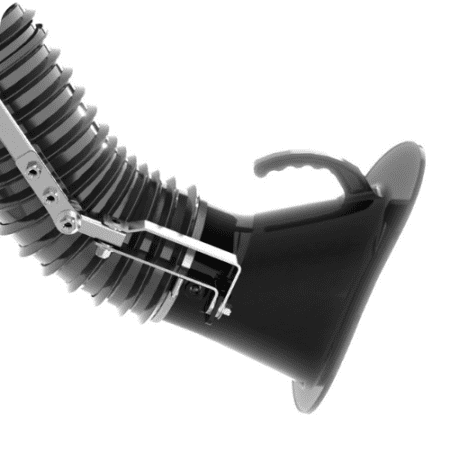

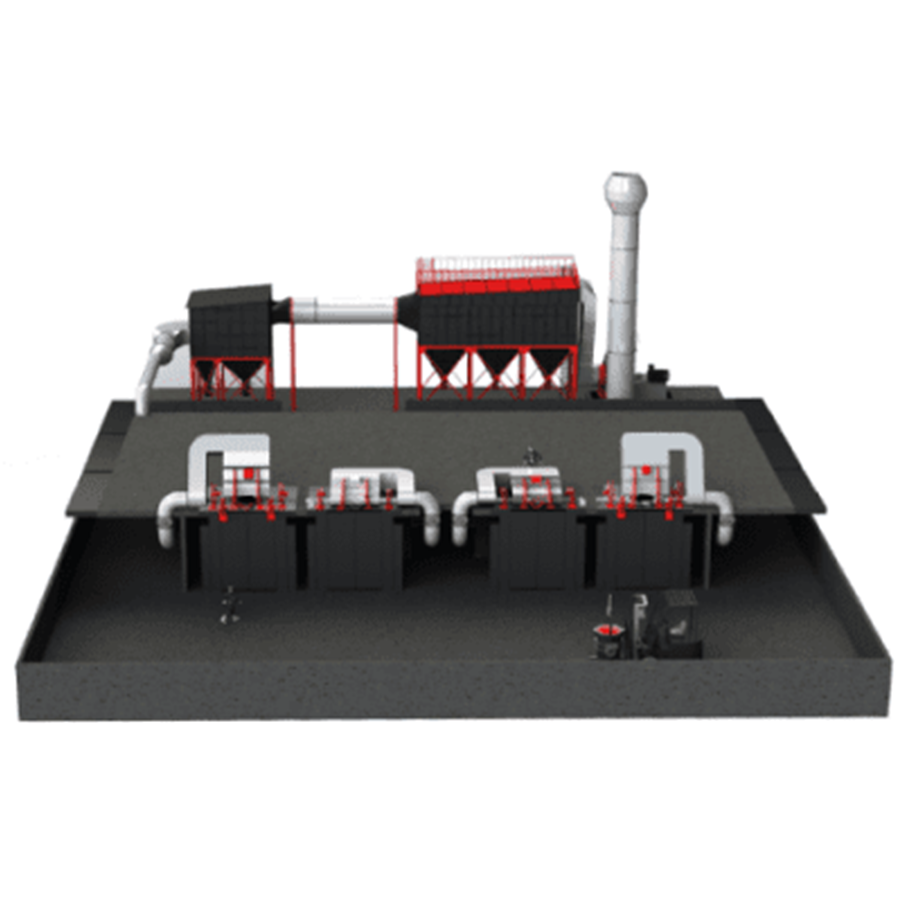

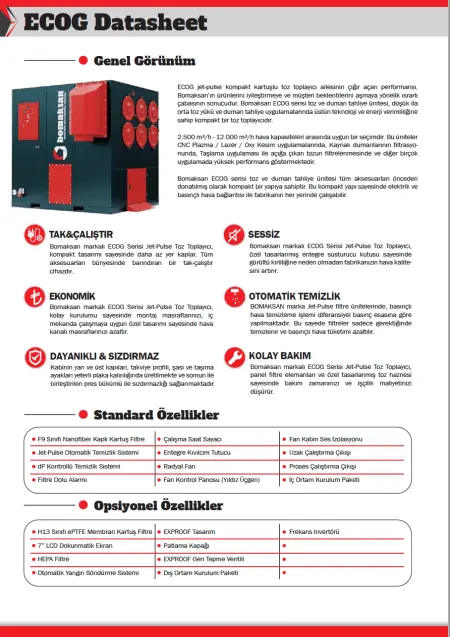

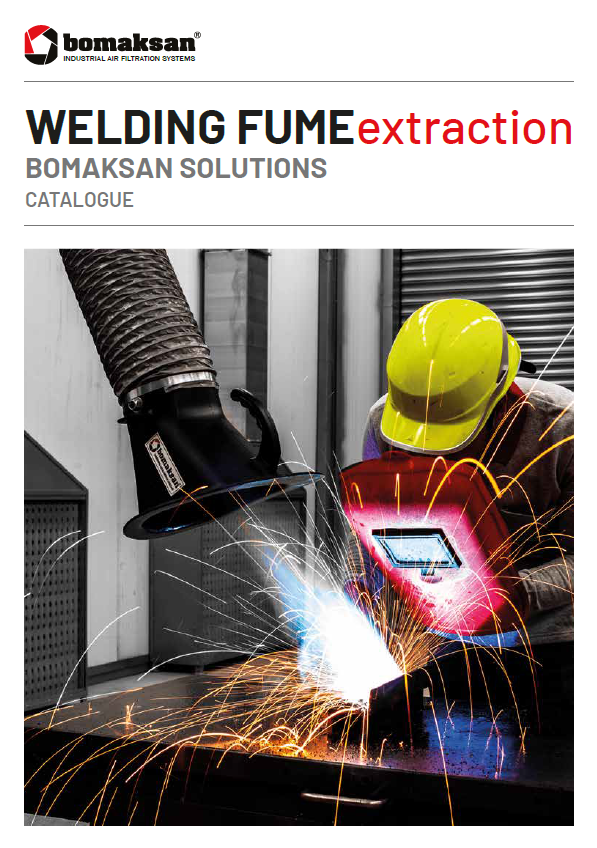

The breakthrough performance of the ECOG family of jet-pulse compact cartridge dust collectors is the result of Bomaksan’s persistent drive to improve its products and exceed customer expectations. Bomaksan ECOG series dust and fume extraction unit is a compact dust collector with superior technology and energy efficiency, from low to medium dust load and fume extraction applications.

It is a suitable choice between 2.500 m / h – 12.000 m³ / h air capacities. These units show high performance in CNC Plasma / Laser / Oxy Cutting applications, in the filtration of Welding fumes, in filtering the dust released through the Grinding application, and in many other applications.

Bomaksan ECOG series dust and fume extraction unit have a compact structure with all their accessories pre-equipped. Thanks to this compact structure, it can work anywhere in the factory with an electrical and compressed air connection.

ECOG series Jet-Pulse Cartridge Filter Units may not be the right solution for your specific need (such as heavy dust loads and absorption of oily fumes /oil mists are some of them). You can consult aBomaksan sales representative in such cases. You can get the right solution at the best prices.

III Catalogs

III Case Studies

WHY BOMAKSAN?

Always With You On Your Way Of Excellence

As Bomaksan, we are aware of your desire to do your job perfectly. Excellence means both producing the best quality product, meeting the quality and deadline expectations of your customers and even exceeding them, creating a healthy and safe working environment and producing without harming the environment.

This is why your investment in Dedusting Systems and Clean Air is actually a direct investment you make to perfect your business.

- Reliable Partner With 35 Years Of Experience!

- ECO-Friendly Engineering Solutions.

- Solutions For Safe Working Environments

- Durable & Sustainable Solutions

Consult Our Clean Air Experts For A More Perfect Production Experience

You can leave your contact information for our Clean Air Experts to provide you with the best support.

You can leave your contact information for our Clean Air Experts to provide you with the best support.

We will try to answer you as soon as possible. In some cases, the response time may be 48 hours.

Bomaksan Dust Collection. It is an expert brand that has entered the production of Gas Treatment and Filtration devices and has managed to make a name for itself in the sector in a short time.

E-Newsletter Subscription

© 2017 - 2022 Bomaksan Industrial Air Filtration Systems. All Rights Reserved.