Menu

Close

Welding Fume

> Applications > Welding Fume

III Welding Fume Extraction Systems

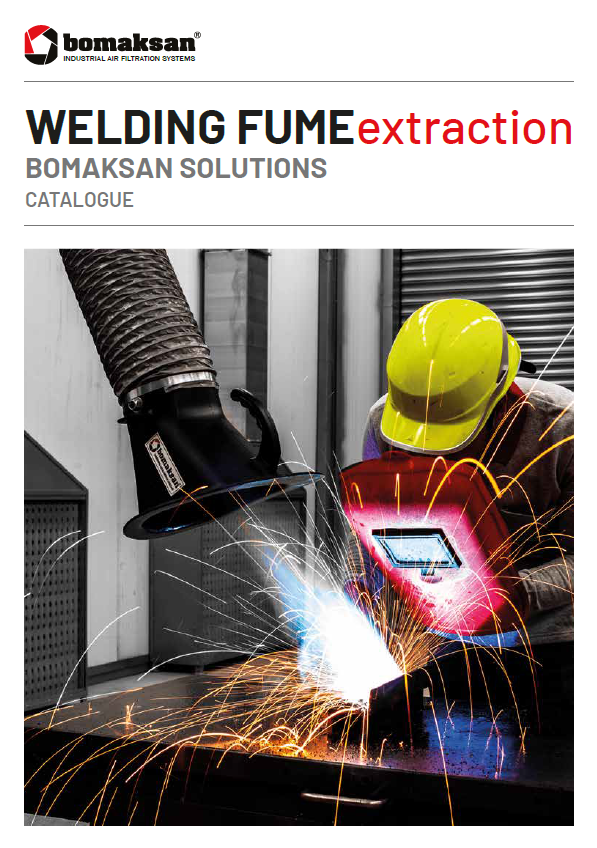

Maintaining clean air in the welding industry protects welders from serious health risks, enhances productivity, and ensures regulatory compliance.

Welding of metals causes the generation of fume and fine particles harmful to health. If this fume and fine particles cannot be discharged from the working environment correctly, it causes an unhealthy working environment. Unhealthy work environments lead to production losses, inefficiencies, and employee unrest.

Companies, which do not increase precautions against occupational accidents and diseases are experiencing a shortage of qualified personnel and face lawsuits with serious consequences in the long term because of the increased awareness in recent years. Companies that take precautions against work accidents and occupational diseases at the highest level have increased productivity thanks to employee satisfaction as well as providing a sustainable production center.

Why Fume Extraction?

Do you know how welding fume and related particles effect on your business and colleagues? Learn more by clicking the below button and downloading our latest article.

III Why Fume Extraction?

HEALTH RISKS

Being exposed to fumes generated by welding or thermally generated particles is a significant health and safety concern for manufacturers. The potential health hazards span from minor illnesses like a sore throat and eye irritation to more severe conditions like metal fume fever, and can even extend to long-term or fatal illnesses such as cancer. In 2019, International Agency of Research classified weld fume as a known carcinogen.

LOSS OF PRODUCTION

Unregulated dust and fumes also have negative effects on factories efficiency. Dust and particles arises from metalworking procceses can penetrate machinery or electrical enclosures, leading to operational downtimes and reduced efficiency.

Additionally, these particles can build up on inventory, necessitating extra cleaning efforts and maintenance work. Moreover, qualified workers would like to work dust-free environments. So they make their choices accordingly.

III What is LEV?

LOCAL EXHAUST VENTILATION

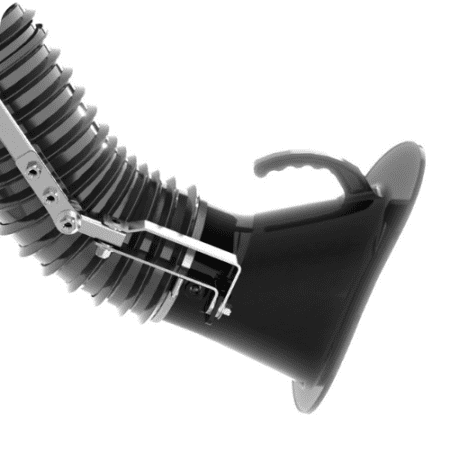

LEV refers to a system used to control and capture airborne contaminants, such as dust, fumes, vapors and gases at their source before they can disperse into the general work environment.

This system consists of a combination of equipment, such as hoods, ducts, fans, and filters, designed to effectively remove pollutants generated during various industrial processes, manufacturing activities, or other work tasks. The purpose of a LEV system is to protect workers’ health by minimizing their exposure to potentially harmful substances. By capturing contaminants at the source, LEV systems help maintain a safer and more comfortable working environment while also complying with occupational health and safety regulations.

What is LEV?

Local Exhaust Ventilation (LEV) is one of the most important technique in ventilation industry. Discover different LEV solutions.

LEV Solutions -

Single Source Extraction

LEV Solutions for single source extraction is important for companies who changes welding stations time to time. Check Bomaksan solutions for single source extraction.

III LEV FOR SINGLE SOURCE

SINGLE SOURCE EXTRACTION

Welding operations may happen different ways. In some processes, welding stations are fixed and do not change frequently. And other processes, welding stations change its locations and positions. In such cases, building a central fume extraction system is not feasable.

Single source extraction devices designed to serve for companies who change welding stations’ position time to time or the location of welding stations are apart from each other.

Bomaksan’s wide range of products consist of followings;

Bomaksan’s wide range of products provides great opportunity for customer to receive the perfect match for their needs.

MULTIPLE SOURCE EXTRACTION

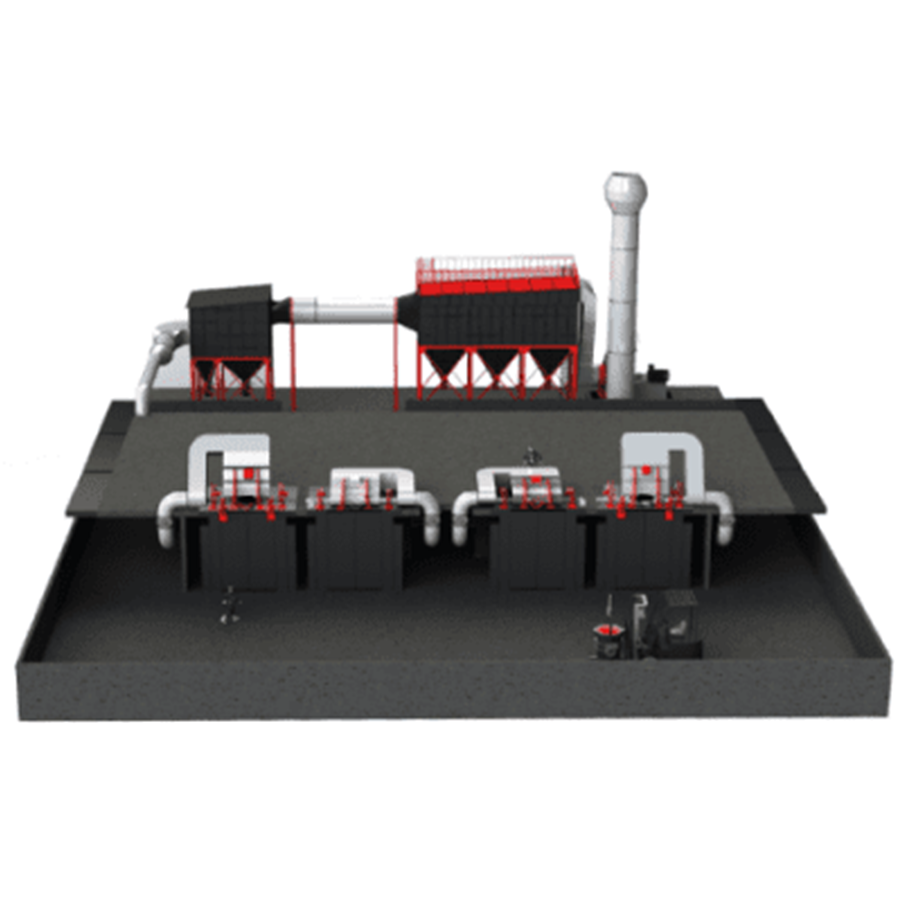

Welding job can be performed in fixed welding stations. In such cases building a central fume extraction system is the correct answer.

Central fume extraction systems or multiple source extraction systems is feasable investment for companies who do not change welding stations locations frequently. If they are combined with heat recovery systems, the time period of return of investment would be very low.

Making heat recovery investment is very important especially for heated production hall. The companies can save a lot of energy by recovering some or all of this heat.

Bomaksan’s wide range of central extraction products consist of followings;

Bomaksan has great expertise in designing and executing perfect LEV systems. Bomaksan project designing, product manufacturing and installation ability allow customers to focus on their own production rather than collaborating different parties.

LEV Solutions -

Multiple Source Extraction

LEV Solutions for multiple source extraction is important for companies who fixed welding stations. Check Bomaksan solutions for multiple source extraction.

General Hall Ventilation

General Hall Ventilation is important to increase indoor air quality. It is perfect when either LEV solutions are not applicable or LEV solutions are not efficient enough.

GENERAL HALL VENTILATION

Main purpose of General Hall Ventilation systems is to increase indoor air quality. They do not extract the pollution from it’s source, but clean the indoor air.

GHV with integrated filtration systems helps companies to recover the heat more efficiently. In that way they can save heating energy and lower the time period of return of investment. There are several different technique to clean the indoor air with hall ventilation system and the most efficient one is Layered Ventilation Technique.

Bomaksan GHV Systems follow the Layered Ventilation Technique in order to increase the system efficiency.

Bomaksan has different GHV solutions;

Bomaksan has great expertise in designing and executing perfect GHV systems. Bomaksan project designing, product manufacturing and installation ability allow customers to focus on their own production rather than collaborating different parties.

FUME EXTRACTION FOR ROBOTIC WELDING

Robotic welding can generate significant amounts of welding fumes, which, if not controlled, can disperse throughout the workspace. Efficient fume extraction is crucial to prevent these airborne contaminants from affecting the health of workers and polluting the environment.

Designing a correct and efficient fume extraction system for robotic welding processes could be complicated. Movement of the robot, or complexity of the processing part determine the type of extraction and filtration systems.

If applicable, LEV systems are the best option for the fume collection and filtration challenge. However it is not always possible. In such cases LEV systems should be supported with General Hall Ventilation solutions.

Bomaksan has great expertise in designing and executing welding fume extraction systems for Robotic Welding or Automatic Welding operations. Bomaksan’s wide range of products helps you find the most convenient solution.

Robotic Welding Processes

Robotic welding becomes a widely adopted and standard solution across diverse industrial fields. While offering notable advantages, this technology also presents

various challenges, and among these challenges, managing fume extraction is one of the biggest.

III Example Applications

III Related Products

III Related Brochures

Are You Looking For A Solution?

Bomaksan Clean Air Experts are here for you. Fill the request form now, get one step closer to the solution.

WHY BOMAKSAN?

Always With You On Your Way Of Excellence

As Bomaksan, we are aware of your desire to do your job perfectly. Excellence means both producing the best quality product, meeting the quality and deadline expectations of your customers and even exceeding them, creating a healthy and safe working environment and producing without harming the environment.

This is why your investment in Dedusting Systems and Clean Air is actually a direct investment you make to perfect your business.

- Reliable Partner With 35 Years Of Experience!

- ECO-Friendly Engineering Solutions.

- Solutions For Safe Working Environments

- Durable & Sustainable Solutions

Consult Our Clean Air Experts For A More Perfect Production Experience

You can leave your contact information for our Clean Air Experts to provide you with the best support.

You can leave your contact information for our Clean Air Experts to provide you with the best support.

We will try to answer you as soon as possible. In some cases, the response time may be 48 hours.

Bomaksan Dust Collection. It is an expert brand that has entered the production of Gas Treatment and Filtration devices and has managed to make a name for itself in the sector in a short time.

E-Newsletter Subscription

© 2017 - 2022 Bomaksan Industrial Air Filtration Systems. All Rights Reserved.