Menu

Close

Foundry

> Applications > Foundry

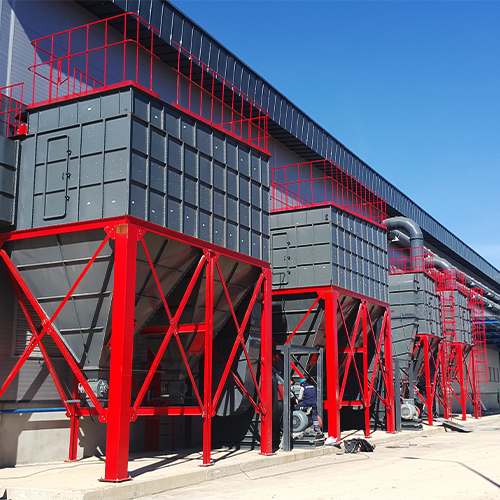

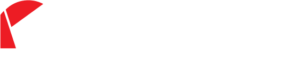

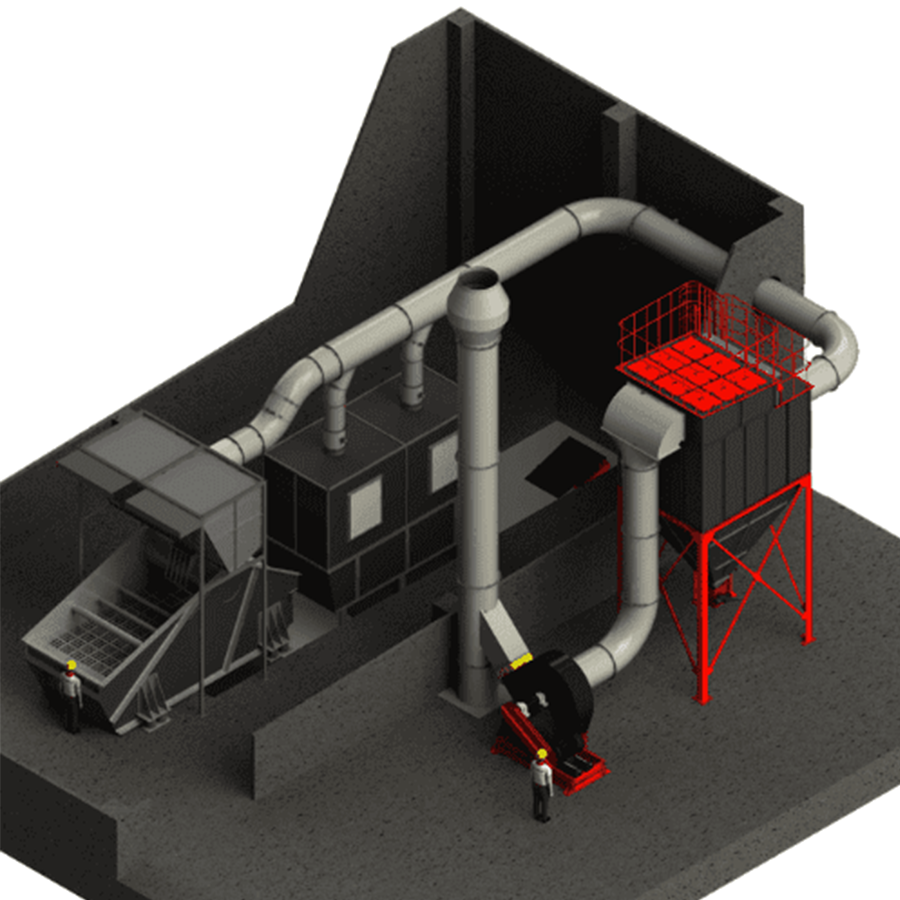

III Foundry Dust & Fume Extraction Solutions

Minimize operating and maintenance expenses by ensuring safe, clean, and efficient production through comprehensive dust and fume extraction solutions at every stage of the foundry process.

Protect your production and employees from toxic and acidic gases generated during foundry processes while surpassing emission regulations. Our comprehensive dust and fume extraction solutions for foundries and smelters ensure protection throughout your entire industrial process.

Melting Furnaces

Check our latest brochure on Melting Furnaces Dedusting Systems.

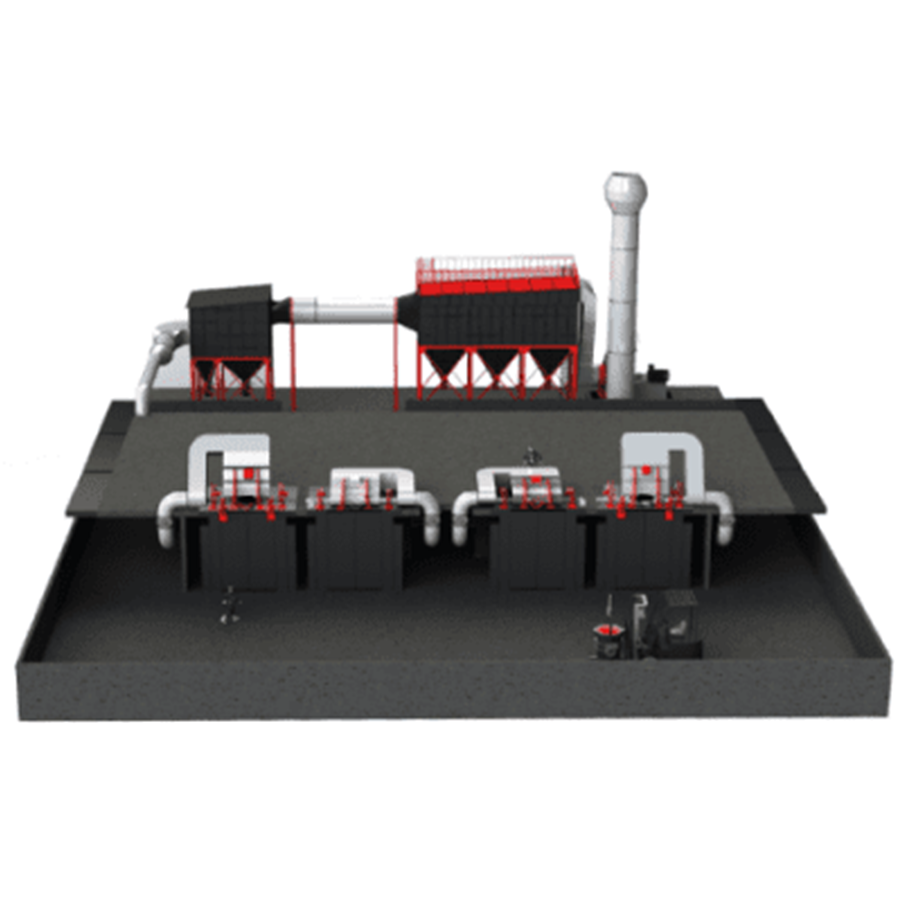

III Melting Shops & Furnaces

Dust & Fume extraction and collection from induction furnaces,pouring and cooling lines are highly important for;

- Productivity

- Health & Safety

- Indoor Air Quality

- Sustainability

- Compliancy

- Environment

Bomaksan working closely with well-known OEM’s in furnaces and melting shops to provide the best solution for foundries. Extraction from induction furnaces, will be achived via OEM hydraulic induction furnace hoods in all working conditions; charging, melting, holding, skimming, pouring and re-pouring. Dust and fume from magnesium treatment using the pour-over method can be collected either via the furnace hood or by roof-top extraction.

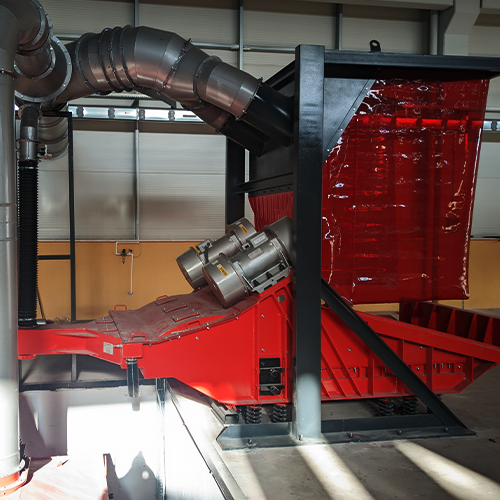

III Sand Reclamation

Dust & Fume extraction and collection from sand reclamation plants (mechanical, thermal etc.) are highly important for;

- Savings in additives consumption (phenolic resins, furan binders etc.)

- Surface quality of final products

- Optimize equipment performance

- Health & Safety

- Environment

Dust is something unwanted in sand moulds because of several reasons. The main reasons are problems in bonding and bad surface quality. In order to bond reclamated sand and additives effectively, dust need to be removed. Otherwise additive consumption could be high. Burnt dust in sand mould create voids on the surface of end products.

Bomaksan working closely with well-known OEM’s in sand reclamation plant to provide the best solution for foundries.

Sand Reclamation

Do you know why do you need a dedusting system for Sand Reclamation?

Grinding & Polishing

Learn why dedusting and fume extraction of grinding process is important.

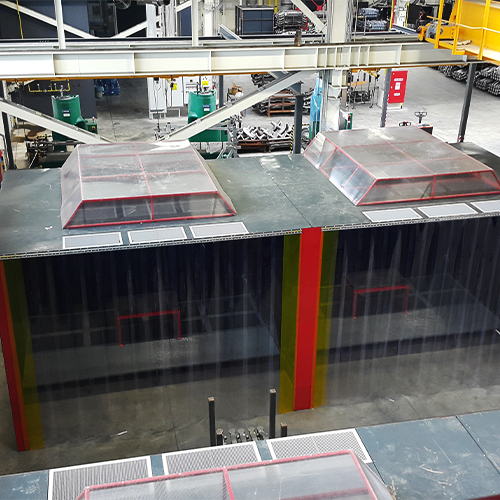

III Grinding & Polishing

Dust & Fume extraction and collection from grinding, sand & shot blasting applications are highly important for;

- Surface quality of final products

- Indoor air quality

- Health & Safety

- Environment

Whether it is grinding of a small part or big part, there are lots of dust & fume arises from grinding application. This dust & fume needs to be extracted and collected efficiently to keep your working environment healthy and safe.

The main purpose of the grinding, sand and shot blasting application is to clean the surface of the end product and provide high quality finishing. To do that, workers or robots are trying to remove the undesired small parts from product’s surface. This process generates high amount of dust & fumes and need to be extracted to achieve higher surface quality.

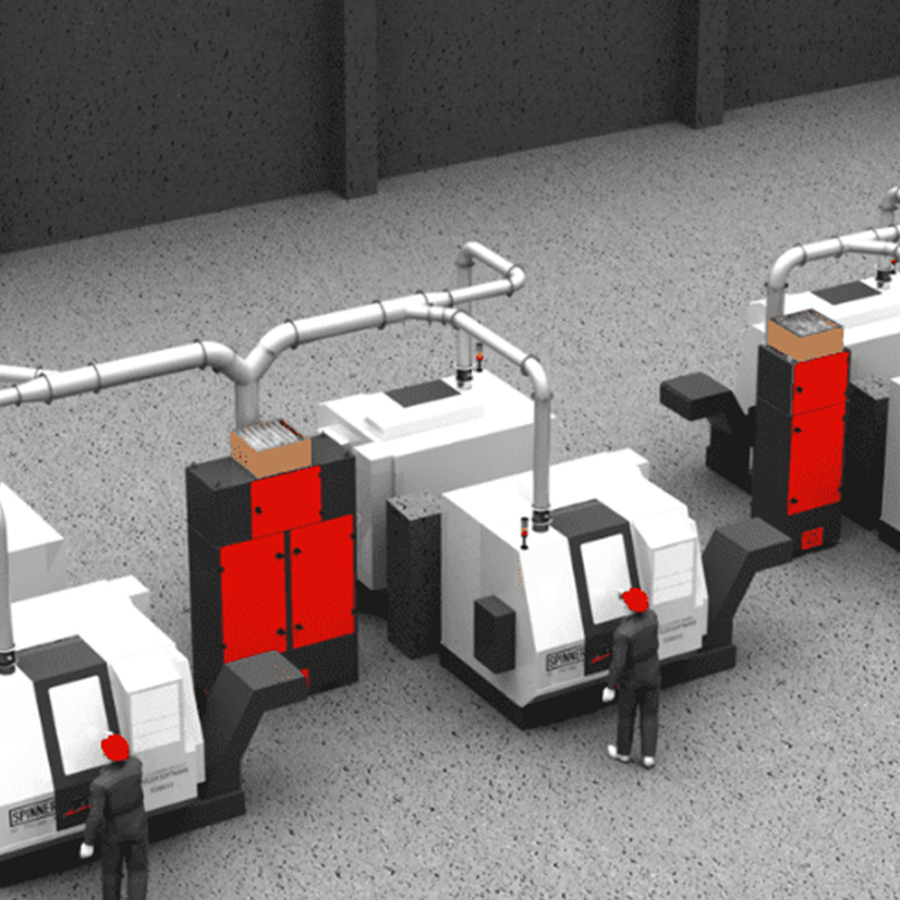

III Machining

Oil Mist extraction and filtration from machining applications are highly important for;

- Surface quality of final products

- Indoor air quality

- Health & Safety

- Environment

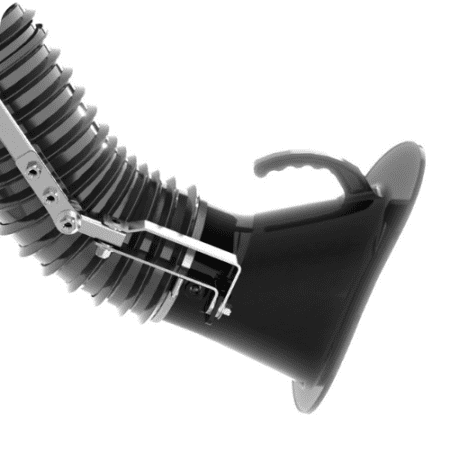

During CNC Machining, oil, emulsions or water is generally using to lubricate or cool the metals. Because of high temperature on contact surface between the mill and metal, those liquids evaporate. This evaporated vapor generally called as oil mist and need to be extracted and filtered to keep machine parts clean.

Mist is defined as liquid droplets smaller than 20 microns. Those droplets are generally generated from CNC Machines in Foundries. The main purpose of oil mist collection and filtration is to provide safer and healthier working environment.

III Refferences

III Example Applications

Bayık Demir

Induction Furnace FES

AYD Automotive

Induction Furnace FES

Azertexnolayn

Induction Furnace FES

Cooling Line FES

Dirikanlar Automotive

DISA Line FES

ELSAN

Furnace FES

SARBAK Metal

Furnace FES

Kamlit KZ

Grinding Benches and Filtration

Parsan

Grinding Benches and Filtration

Parsan

Grinding Benches and Filtration

Innometal

Vibration Screen Dust Collection

III Case Studies

Are You Looking For A Solution?

Bomaksan Clean Air Experts are here for you. Fill the request form now, get one step closer to the solution.

WHY BOMAKSAN?

Always With You On Your Way Of Excellence

As Bomaksan, we are aware of your desire to do your job perfectly. Excellence means both producing the best quality product, meeting the quality and deadline expectations of your customers and even exceeding them, creating a healthy and safe working environment and producing without harming the environment.

This is why your investment in Dedusting Systems and Clean Air is actually a direct investment you make to perfect your business.

- Reliable Partner With 35 Years Of Experience!

- ECO-Friendly Engineering Solutions.

- Solutions For Safe Working Environments

- Durable & Sustainable Solutions

Consult Our Clean Air Experts For A More Perfect Production Experience

You can leave your contact information for our Clean Air Experts to provide you with the best support.

You can leave your contact information for our Clean Air Experts to provide you with the best support.

We will try to answer you as soon as possible. In some cases, the response time may be 48 hours.

Bomaksan Dust Collection. It is an expert brand that has entered the production of Gas Treatment and Filtration devices and has managed to make a name for itself in the sector in a short time.

E-Newsletter Subscription

© 2017 - 2022 Bomaksan Industrial Air Filtration Systems. All Rights Reserved.