Reducing Maintenance Time In Dust Collection Systems

Whether it is industrial production or not, there are moments in every sector where the planned activities do not take place within the desired time

The most popular method of welding today is mild steel welding, which is important for every industry that uses welding in its production process. Latest scientific research has shown that the gases that this method produces are potentially carcinogenic. Although we have yet to see the full effects of this finding, it is clear that the health and safety of welders and the methods by which they can be ensured will be increasingly based.

How is fume produced by welding?

Welding fume is created by heating up a metal above its boiling point. The vapors that this thermal process creates condense into fine particles, creating a plume suspended in the ambient air in essence. The welder will have to be similar to the manual welding process , due to the need for precision. This suggests that the fume plume, particles and gases will penetrate the welder ‘s breathing zone (< 30 centimeters/12 inches away from the nose and mouth), which is at serious risk of inhaling them..

Although various welding methods produce different amounts of gases, they all contain different concentrations of hazardous substances. The most popular and harmful of these are chrome, manganese , nickel, NOX and CO. Since smaller particles appear to end deeper in the lungs when inhaled, they are considered to pose the greatest health risk, along with the gases..

Welding fumes are carcinogen for humans

In April 2017, new scientific evidence was released by IARC, the International Agency for Cancer Research , showing that mild steel welding fumes can cause human lung cancer (and possibly also kidney cancer). The most immediate legislative outcome of this was that the Health and Safety Executive (HSE), an organisation committed to occupational safety, reclassified mild steel welding fume as a human carcinogen in the United Kingdom.

Since general venting does not achieve the necessary emission control, the HSE has issued a change in compliance expectations, meaning that all businesses conducting welding activities must ensure effective engineering controls to prevent employees from welding exposure to fumes. HSE can no longer tolerate any welding performed without any adequate exposure control measures in place, irrespective of the duration, as there is no defined degree of safe exposure.’ (Source: www.hse.gov.uk)

Various welding processes require alternative extraction solutions

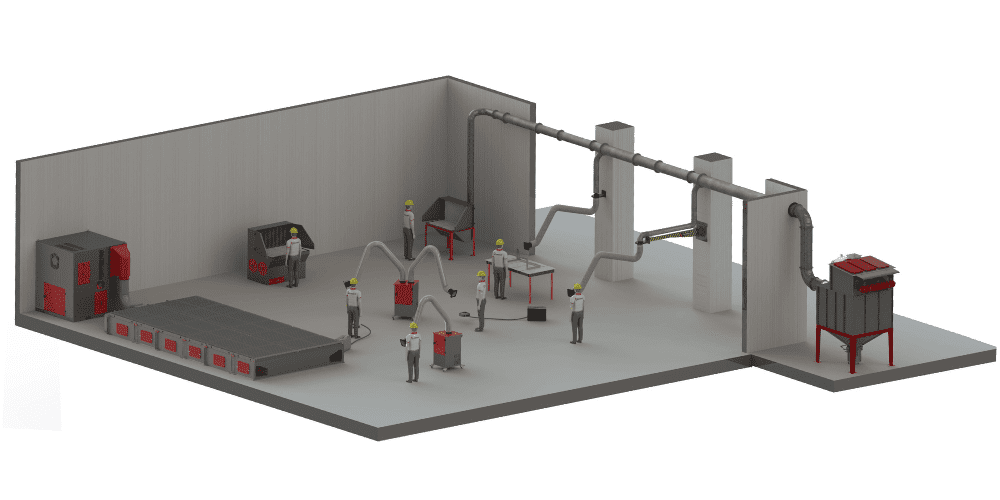

The most effective method of capturing and extracting fumes has been found to be at-source extraction (also known as at-source capture and LEV; Local Exhaust Ventilation). The reasons why at-source extraction is the most effective one are that it captures all the fumes and gases before operator breathe and required energy consumption is the lowest in at-source extraction method.

However it is not always applicable to use at-source or LEV systems. In some applications welder change its welding position very frequently. This mostly happens in welding of big parts. In such system alternative extraction systems may be helpful such as Bomaksan’s ALVER model AIR TOWERS or PUSH-PULL extraction systems.

Stationary devices – such as extraction arms, or welding and grinding tables – remain the most common means of fume extraction, and will continue to be, as they will replace recirculating systems in several long time welding operations.

New generation welders: Welding Robots

With the rapid advancement of technology, robots continue to enter our lives day by day. In these days, when technologies that shape the future such as Industry 4.0 have begun to gain important places in our lives, it is inevitable that welding operations are also automated and robots are used more and more every day.

Welding robots are used in many industries today. Welding robots, which have become widespread with the use of the automotive industry, are used in many manufacturing industries as of today.

Of course, welding fumes and gases are released as a result of the operation of welding robots. The biggest difference between the welding fume created by the robot operator and the human operator is that the robot operators do not breathe. For this reason, when designing welding fume extraction and filtration systems, we do not have to worry about catching the smoke before the robot breathes. This concern is replaced by capturing and filtering the welding fumes emitted from different points before it spreads to other parts of the manufacturing area. Bomaksan, which produces alternative solutions in this context, has many references in robot welding applications..

Health and safety requirements for welders are likely to continue to improve

Although forecasting potential welding regulations is difficult to make, there are other predictions that we can make about the industrial welding itself. Although several welding processes used to include many different segments, a more multifaceted welding method is much simpler nowadays. This includes complex motions and multiple parts being welded together at a single stage of manufacturing, assisted by tailor-made fume extraction at the source, or making a component as a single part in a 3D printing process.. .

Why not only extraction but also filtration?

You may think that it will be sufficient to remove the welding fumes from the environment to protect the health of welding operators and workers, and there is no need for filtration. In this case, welding fumes can be extracted from each welding operator with a central fan and released into the atmosphere. However, this will cost your business multiple times;

1. If indoor air is heated, you will not have a chance to recover this heated air. However, with an effective filtration system, you can return all the air you suck back to the indoor environment and provide significant energy savings.

2. It is not possible to use mobile / portable systems without filtration. Otherwise, you will take the harmful fume and smoke from one place and move it to another.

3. You must stay within the emission level to the atmosphere in accordance with the laws of the local governments you are affiliated with. Depending on the density and type of welding fumes, you may not be able to emit without filtering it into the atmosphere.

It is not risk-free if it is not fume-free

Health problems that may occur as a result of welding operators inhaling harmful welding fumes have also started to be described as work accidents. The main reason for this is that the damages of welding fumes are beginning to be accepted by medical authorities. For this reason, companies that do not take adequate precautions for welding fume extraction and filtration carry a risk in terms of occupational safety..

Everyone wins from a safe and clean working environment

Companies installing successful fume extraction systems will also make the difference very quickly, as when these gases are properly removed, their factories and workshops become significantly cleaner. Such a climate would lead to happier employees, less sick leave and stop early retirement. Businesses with healthy and clean working environments often expect to see results such as higher efficiency , higher product quality and an improved chance of recruiting (and retaining) highly qualified workers..

Case Studies

Whether it is industrial production or not, there are moments in every sector where the planned activities do not take place within the desired time

Project designers and process owners often focus on filtering devices when designing or purchasing a dust collection system. Yet another area they focus on is

Many industrial companies are seeking information on how to evaluate the performance of working dust collection systems. Many researches and articles which process owner refers

© 2017 - 2022 Bomaksan Industrial Air Filtration Systems. All Rights Reserved.