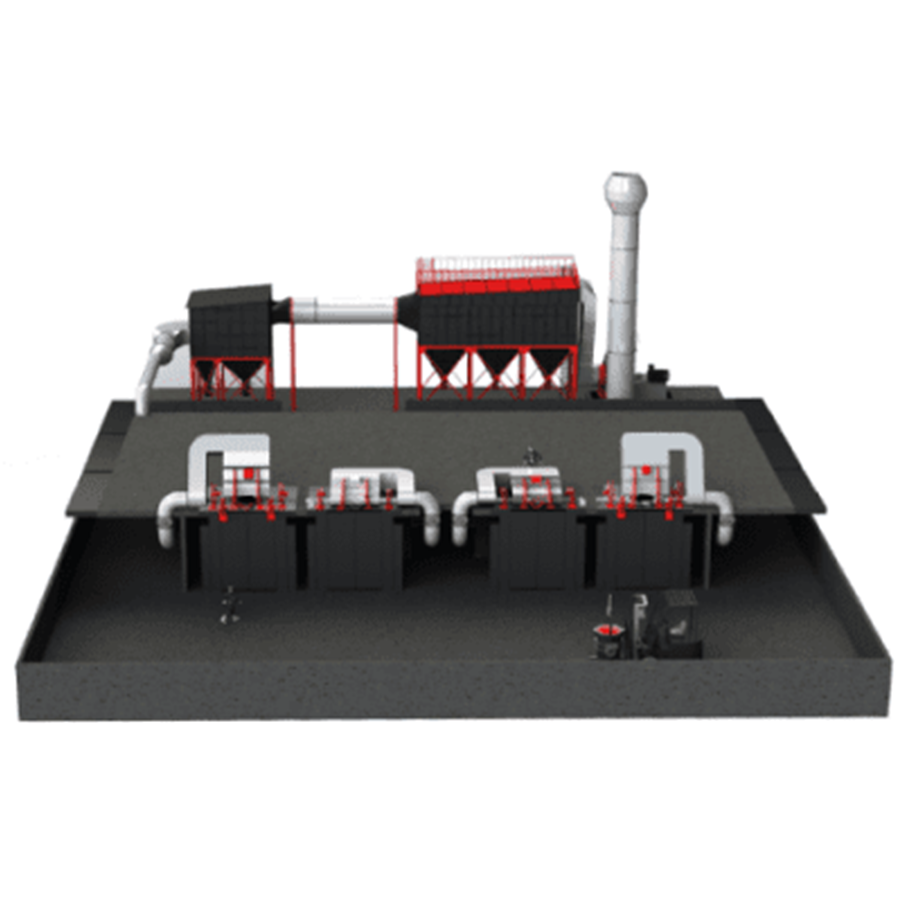

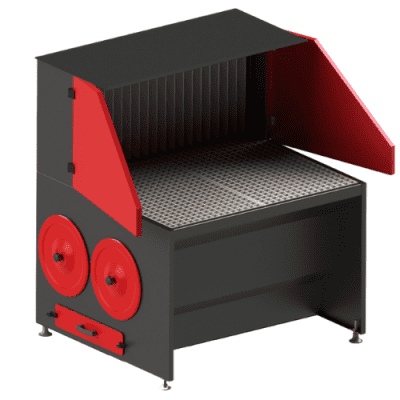

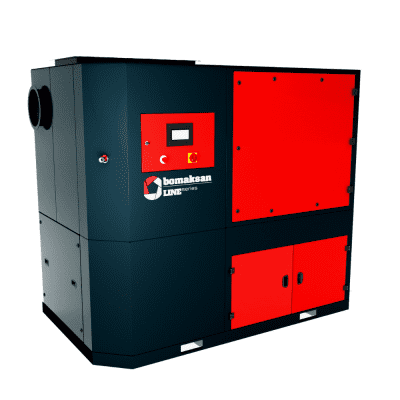

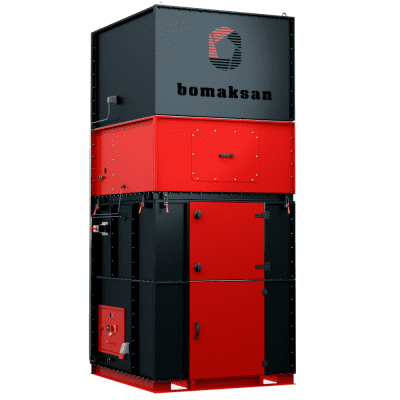

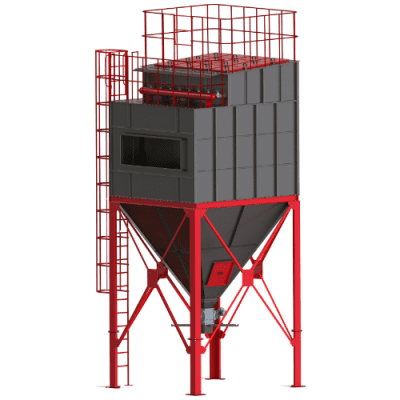

Grinding and polishing tasks are often performed at fixed workstations. In such cases, installing a central dust extraction system is the most effective and efficient solution.

For companies where workstation locations remain stable, a central or multi-source extraction system is a feasible and long-term investment. When combined with heat recovery technology, the return on investment can be significantly accelerated.

This is especially important in heated production halls, where recovering some or all of the extracted warm air helps reduce energy costs and supports sustainability goals.