Menu

Close

CNC Laser & Plasma Cutting

> Applications > CNC Laser & Plasma Cutting

III Dust and Fume Extraction Solutions for CNC Plasma and Laser Cutting

Removing harmful fumes and fine dust during CNC plasma and laser cutting protects workers, extends equipment life, and keeps your facility compliant and efficient.

CNC plasma and laser cutting processes release hazardous dust and fumes that pose serious risks to worker health and workplace safety. Without effective extraction, these airborne pollutants accumulate in the environment, leading to reduced air quality, increased equipment contamination, and long-term health complications. In today’s industrial landscape, companies that fail to manage these risks face growing pressure due to regulatory enforcement and workforce expectations. On the other hand, businesses that prioritize advanced fume and dust control benefit from a safer work environment, higher employee retention, and more sustainable productivity.

III How Contamination Arises in Thermal Cutting Process?

Technologies like plasma, laser and oxy-cutting are developed to cut the sheet metal plates into workpieces. To do that, the torch in the thermal cutting machines needs to provide intense heat to cut the sheet metal plates. This intense heat melts and vaporizes the workpiece material.

When the cutting temperature exceeds the boiling point of the material, it causes metals (like iron, zinc, or chromium) to vaporize into a fine mist. As the vapor cools rapidly in the air, it condenses into solid particles, forming submicron metal oxides. The presence of oxygen during plasma or laser cutting leads to exothermic oxidation. For example, iron reacts with oxygen to form iron oxide particles, contributing to fume emissions

III WHY DO YOU NEED A FILTRATION SYSTEM?

In thermal cutting processes, the generation of metal fumes, gases, and dust presents significant risks. These airborne particles pose risks not only to machinery but also to the health and safety of the workforce. Implementing an effective filtration system is essential for several critical reasons:

1. Employee Health and Safety

Fume and dust generated during CNC plasma and laser cutting contain ultrafine metal particles and toxic gases such as hexavalent chromium and zinc oxides. These airborne contaminants easily penetrate the respiratory system, causing conditions like metal fume fever, chronic respiratory issues, and skin irritation. Long-term exposure to such hazardous substances severely impacts worker well-being. Installing a reliable CNC plasma fume control and dust extraction system is essential to ensure occupational safety and to create a healthier, legally compliant work environment.

2. Compliance with Environmental and Safety Regulations

Industries that rely on thermal cutting processes are increasingly subject to strict occupational exposure limits and air quality regulations. Without proper fume extraction systems for CNC machines, companies risk violating compliance requirements, leading to fines, legal action, or even forced shutdowns. A certified dust collection system helps maintain regulatory compliance, demonstrating a commitment to workplace safety and environmental responsibility.

3. Protecting Machinery and Equipment

Fine metal dust and fumes from CNC plasma and fiber laser cutting processes can infiltrate machinery, causing corrosion, blockages, and optical damage — especially in sensitive components like laser lenses. Over time, unfiltered contaminants lead to frequent breakdowns and increased maintenance costs. An industrial dust collector for metal cutting prevents dust buildup, ensuring long-term equipment reliability. Furthermore, facilities with rooftop solar panels must be especially cautious: conductive metal dust can damage panels, reduce efficiency, and significantly shorten their lifespan. Proper filtration not only protects your machinery but also your energy investments.

4.Improved Productivity and Operational Efficiency

Maintaining clean air with an effective dust and fume extraction system directly impacts productivity. Cleaner environments lead to fewer equipment failures, reduced maintenance, and minimal production delays. By eliminating CNC cutting dust hazards and improving indoor air quality, businesses benefit from improved employee performance and smoother operations. In short, air quality solutions for CNC cutting boost overall efficiency and ensure uninterrupted workflow.

5. Energy Savings and Cost Reduction

Well-designed dust collection systems optimize airflow, improving energy efficiency and reducing the load on HVAC systems. This not only lowers operational costs but also minimizes system wear over time. A high-efficiency fume extractor reduces the need for frequent maintenance and helps maintain a stable thermal balance in the facility. The result is sustainable, long-term cost savings for your cutting operations.

6. Environmental Responsibility and Sustainability

CNC plasma and laser cutting release harmful airborne pollutants that, if left uncontrolled, contribute significantly to environmental degradation. An eco-friendly dust extraction system reduces thermal cutting emissions and minimizes the environmental footprint of your operation. Companies that invest in sustainable air filtration not only comply with environmental standards but also reinforce their commitment to corporate social responsibility and long-term ecological stewardship.

Investing in a high-performance dust and fume extraction system for CNC plasma and laser cutting is not just about meeting safety standards — it’s a proactive step toward protecting your team, extending machine life, and achieving long-term operational excellence. From reducing hazardous air pollutants to improving workflow and sustainability, the right system transforms your facility into a safe, compliant, and efficient production environment.

III CHOOSING THE RIGHT FILTRATION SYSTEM FOR YOUR PROCESS

Particle Size and Filtration Efficiency: Thermal cutting produces fine particles and gases. Use high-efficiency filters, to capture submicron metal fumes effectively.

Type of Material and Emissions: Different materials (e.g., stainless steel, aluminum, mild steel) release different pollutants. Additionally, residual oil on the surface of the material can evaporate during operation, leading to rapid clogging of standard filters. Ensure the filtration system is designed for the specific contaminants your process generates.

How to Choose Right Dust Collector?

Selecting the appropriate filtration system for thermal cutting processes is critical for ensuring operational safety and efficiency

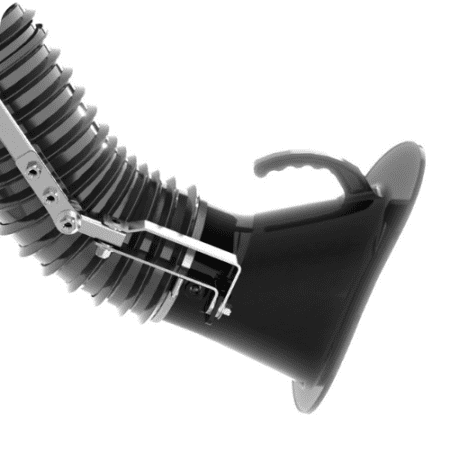

Fire Safety Measures: Thermal cutting generates sparks and hot particles. Additionally, splatters generated during the cutting of thick materials can be captured by the extraction system. Choose filtration systems with fire prevention features, such as spark arrestors or integrated fire suppression systems. Please note that when cutting materials thicker than 10 mm or any thickness of aluminum, additional precautions should be taken.

Energy Efficiency: The airflow requirements of thermal cutting systems largely depend on the design of the cutting table. Modular cutting tables with divided extraction zones require less extraction power, whereas single-module cutting tables demand more. The design of the filter unit and fan also significantly impact energy consumption. Partnering with expert dust collection manufacturers can help reduce energy costs.

Maintenance and Filter Longevity: Select systems with durable, easy-to-maintain filters that minimize downtime and reduce replacement frequency. Automated cleaning mechanisms can help maintain consistent airflow and efficiency.

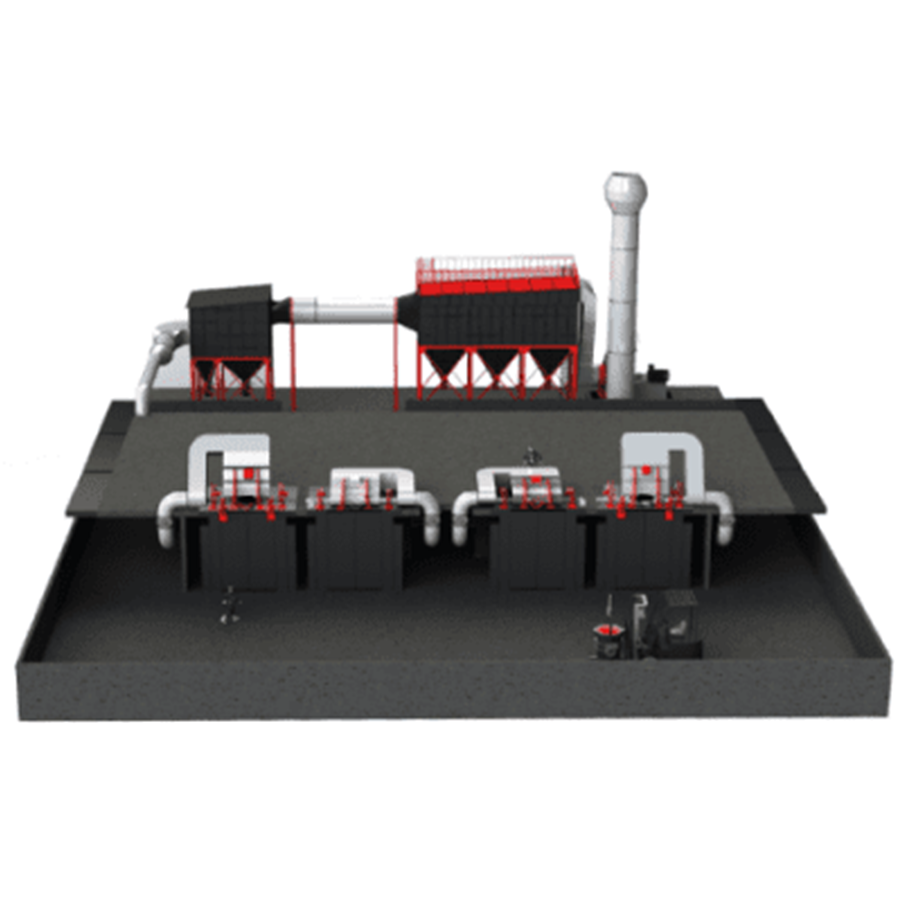

At Bomaksan, we understand the unique challenges of thermal cutting operations. With over 35 years of experience, we offer customized filtration solutions that ensure optimal safety, energy efficiency, and performance. Our systems are designed to meet your specific operational needs, keeping your facility compliant, productive, and safe. Reach out to Bomaksan today for expert advice and tailored solutions for your cutting processes.

III Example Applications

Are You Looking For A Solution?

Bomaksan Clean Air Experts are here for you. Fill the request form now, get one step closer to the solution.

WHY BOMAKSAN?

Always With You On Your Way Of Excellence

As Bomaksan, we are aware of your desire to do your job perfectly. Excellence means both producing the best quality product, meeting the quality and deadline expectations of your customers and even exceeding them, creating a healthy and safe working environment and producing without harming the environment.

This is why your investment in Dedusting Systems and Clean Air is actually a direct investment you make to perfect your business.

- Reliable Partner With 35 Years Of Experience!

- ECO-Friendly Engineering Solutions.

- Solutions For Safe Working Environments

- Durable & Sustainable Solutions

Consult Our Clean Air Experts For A More Perfect Production Experience

You can leave your contact information for our Clean Air Experts to provide you with the best support.

You can leave your contact information for our Clean Air Experts to provide you with the best support.

We will try to answer you as soon as possible. In some cases, the response time may be 48 hours.

Bomaksan Dust Collection. It is an expert brand that has entered the production of Gas Treatment and Filtration devices and has managed to make a name for itself in the sector in a short time.

E-Newsletter Subscription

© 2017 - 2022 Bomaksan Industrial Air Filtration Systems. All Rights Reserved.