Menu

Close

Material Processing

> Applications > Material Processing

III Dust Collection in Material Processing

Material processing applications—especially those involving bulk granular materials like aggregates, minerals, and powders—generate large volumes of fine and hazardous dust during handling, conveying, and processing stages. These airborne particles pose serious risks to worker health and safety, compromise product purity, cause excessive wear on equipment, and increase the likelihood of fire or explosion incidents.

To ensure a safe and efficient working environment in material processing operations, where bulk granular materials such as minerals, grains, and powders are handled, effective dust control is essential—not optional.

Key dust sources such as silos, hoppers, screens, grinders, conveyors, and transfer points continuously release fine particulate matter during loading, unloading, crushing, and sieving. Without proper extraction systems, this dust accumulates on equipment, penetrates control panels, and endangers workers’ respiratory health—creating both operational inefficiencies and serious health risks.

Particularly, respirable crystalline silica from materials like quartz can lead to chronic illnesses such as silicosis. Additionally, combustible dust from organic or chemical materials increases the risk of fire and explosion, especially in enclosed or poorly ventilated spaces.

Installing an industrial-grade dust collection and filtration system significantly reduces these risks, enhances machinery durability, lowers maintenance needs, and ensures compliance with safety standards such as OSHA, NFPA, and ATEX.

Why Clean Air?

In material processing operations, clean air is not a luxury—it’s a fundamental requirement for protecting worker health, maintaining the efficiency of handling and conveying systems, preventing damage to sensitive machinery, and ensuring the long-term success and sustainability of bulk material processing facilities.

III Why Need Dust Collection?

Health & Safety First

Clean air is essential in material processing operations where bulk granular materials such as minerals, powders, and aggregates are handled. Harmful airborne dust—especially respirable crystalline silica and fine particulates generated during crushing, conveying, or bagging—can lead to chronic respiratory diseases, fatigue, and even cancer. Protecting workers from these risks starts with effective dust extraction.

Equipment Efficiency

Dust buildup on crushers, screens, conveyor motors, and control panels causes system overheating, unplanned stoppages, and excessive wear. By controlling airborne dust, facilities can minimize downtime, reduce maintenance costs, and extend the life of critical machinery.

Regulatory Compliance

Material processing facilities must meet strict air quality standards imposed by occupational safety authorities such as OSHA, and comply with explosion protection directives like ATEX. Industrial dust collection systems help ensure legal compliance, reduce liability, and support a safer, more sustainable operation.

III Bomaksan Expertise is with You

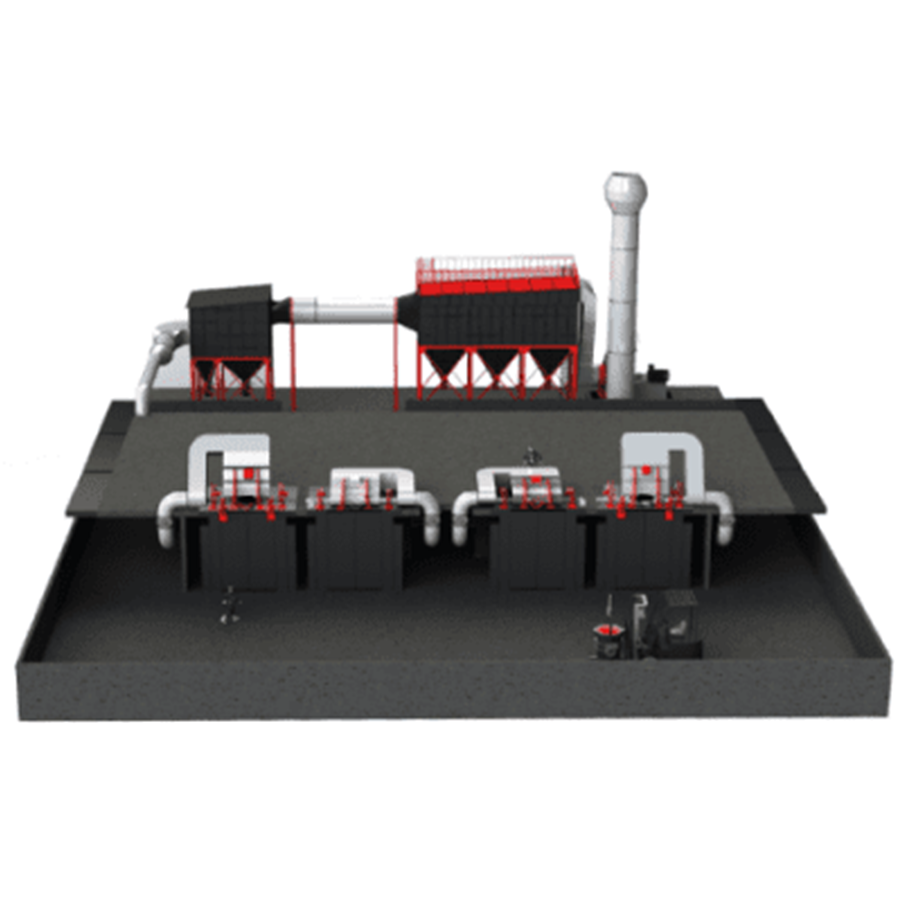

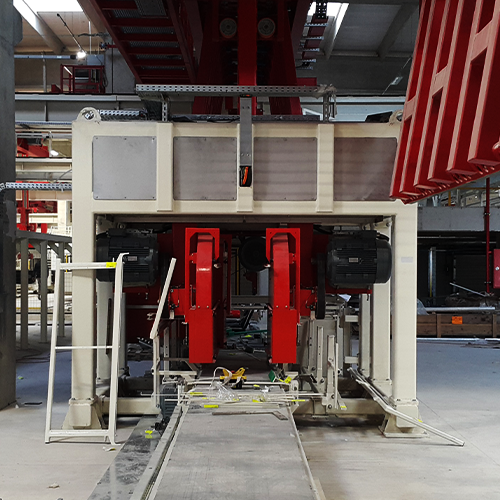

At Bomaksan, we understand that dust-related challenges in material processing—particularly when handling bulk materials like silica, quartz, minerals, or powders—vary significantly depending on the type of raw material, process complexity, and facility layout. That’s why we develop customized extraction and filtration solutions engineered specifically for your operations—whether you’re crushing minerals, transferring bulk powders, or packaging abrasive materials.

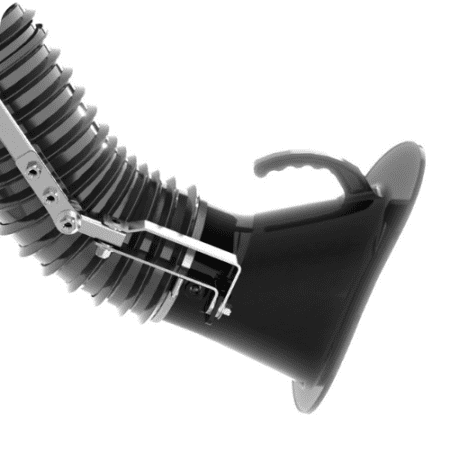

Our systems feature high-efficiency filtration technologies built to handle the intense dust loads common in material processing, while maintaining compact, modular, and energy-saving designs. From localized extraction units to large-scale centralized dust collectors with ATEX-certified safety features, Bomaksan helps you achieve clean air, reliable performance, and full compliance—ensuring that your process remains productive, safe, and sustainable.

III Advantages of Bomaksan Systems

Investing in Bomaksan not only helps you control hazardous dust in material processing operations, but also contributes to a safer workplace, longer equipment lifespan, and enhanced operational efficiency. Here are some of the key advantages that set Bomaksan apart in dust collection solutions for bulk material handling and processing:

Better Indoor Air Quality

Bomaksan systems effectively capture and filter fine dust particles directly at the source during material processing operations. This significantly improves indoor air quality in facilities handling bulk materials such as minerals, powders, and aggregates. As a result, the working environment becomes healthier and safer, airborne contamination is minimized, and visibility in processing areas remains clear.

Reduced Maintenance Requirement and Less Downtime

Dust generated during material processing can quickly accumulate around crushing, grinding, screening, and mixing stations. This buildup leads to frequent equipment failures, unplanned downtimes, and repeated cleaning efforts. Over time, fine and abrasive dust infiltrates sensitive components, and causes corrosion—especially in control panels and automation systems.

Bomaksan’s dust extraction systems, engineered specifically for material processing applications, capture harmful particles directly at the source. This drastically reduces contamination, keeps equipment cleaner and more dependable, and extends the operational life of critical systems.

Compliance with Internatioal Standards

Bomaksan filtration units are manufactured in compliance with international quality and safety standards such as ISO 9001, CE, and relevant occupational health and safety directives. By reducing worker exposure and maintaining high air cleanliness levels, our solutions not only help you meet legal requirements but also enable you to exceed global standards in your operations.

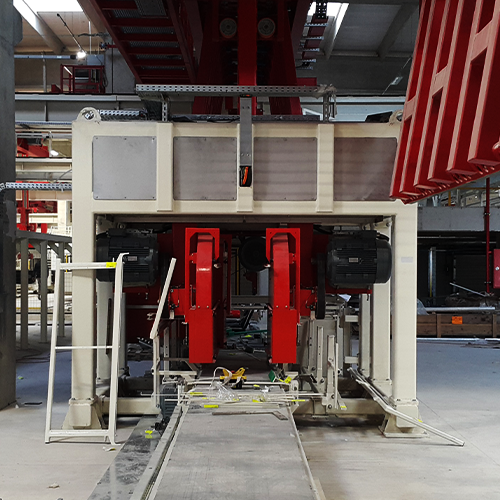

III Example Applications

III Related Products

III Case Studies

Are You Looking For A Solution?

Bomaksan Clean Air Experts are here for you. Fill the request form now, get one step closer to the solution.

WHY BOMAKSAN?

Always With You On Your Way Of Excellence

As Bomaksan, we are aware of your desire to do your job perfectly. Excellence means both producing the best quality product, meeting the quality and deadline expectations of your customers and even exceeding them, creating a healthy and safe working environment and producing without harming the environment.

This is why your investment in Dedusting Systems and Clean Air is actually a direct investment you make to perfect your business.

- Reliable Partner With 35 Years Of Experience!

- ECO-Friendly Engineering Solutions.

- Solutions For Safe Working Environments

- Durable & Sustainable Solutions

Consult Our Clean Air Experts For A More Perfect Production Experience

You can leave your contact information for our Clean Air Experts to provide you with the best support.

You can leave your contact information for our Clean Air Experts to provide you with the best support.

We will try to answer you as soon as possible. In some cases, the response time may be 48 hours.

Bomaksan Dust Collection. It is an expert brand that has entered the production of Gas Treatment and Filtration devices and has managed to make a name for itself in the sector in a short time.

E-Newsletter Subscription

© 2017 - 2022 Bomaksan Industrial Air Filtration Systems. All Rights Reserved.