Menu

Close

Hot-Dip Galvanizing

> Applications > Hot-Dip Galvanizing

III HOT-DIP GALVANIZING FUME EXTRACTION SYSTEMS

Protect your employees, machinery, and galvanizing quality with effective fume and vapor filtration systems. Improve indoor air quality and ensure full compliance with occupational health and safety regulations.

During hot-dip galvanizing processes, high temperatures cause flux, zinc vapor, and other chemical compounds to disperse into the environment, generating harmful fumes and vapors. If not properly controlled, these pollutants spread throughout the work area, degrade indoor air quality, damage equipment, and pose serious health risks to workers.

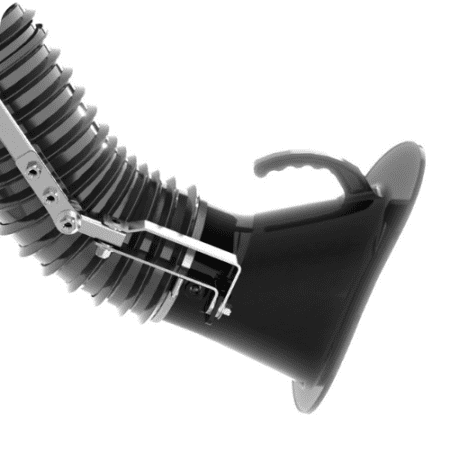

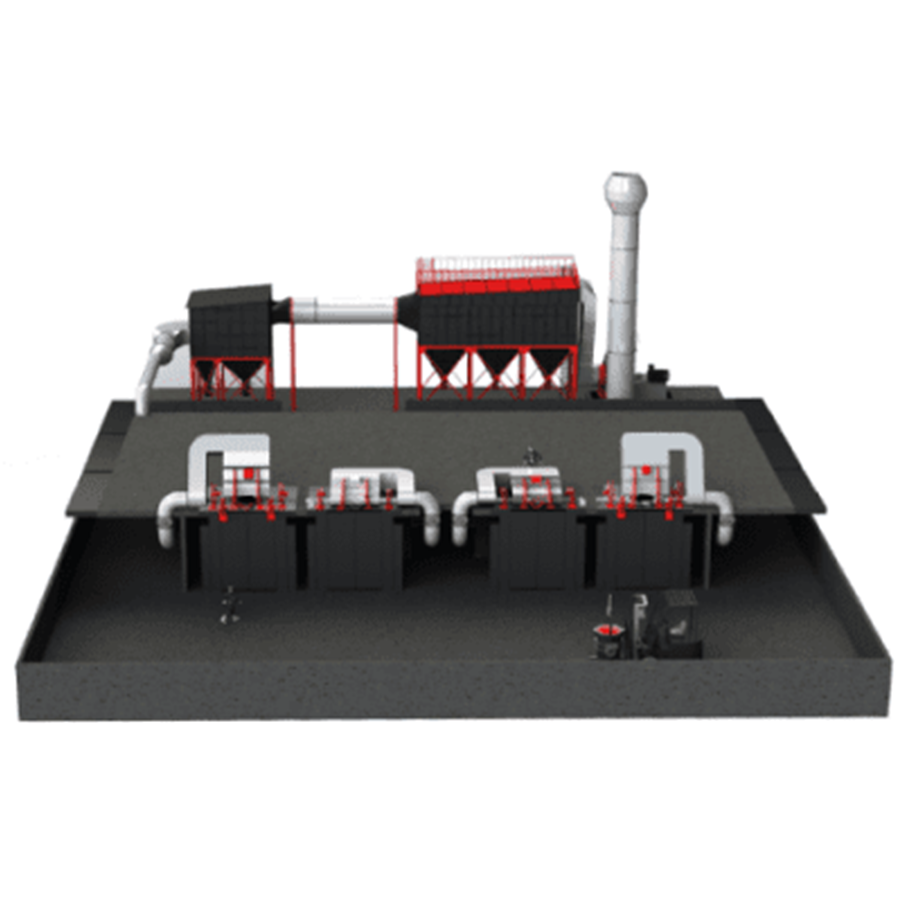

Effective extraction of fumes and vapors generated during galvanizing is essential for maintaining a clean, safe, and legally compliant work environment. Fume extraction systems positioned over the zinc bath significantly reduce the spread of airborne contaminants.

Facilities that implement efficient fume and vapor collection systems not only comply with occupational health and safety regulations but also extend equipment lifespan, lower maintenance costs, and boost productivity by improving worker satisfaction. In galvanizing operations, air quality management is no longer optional — it is a fundamental requirement for safe and sustainable production.

III Why Fume Extraction is Important?

In today’s industrial settings—especially in hot-dip galvanizing processes—zinc vapor and chemical fumes generated at high temperatures disperse into the air, reducing indoor air quality and damaging equipment. If not properly controlled, these hazardous emissions negatively impact both worker health and overall production efficiency.

Reliable fume extraction systems are no longer optional—they are essential. Centralized solutions for vapor control play a critical role in ensuring safe, efficient, and regulation-compliant operations.

Zinc Fume and Acid Vapor Hazards

The hot-dip galvanizing process is a widely used method for providing long-lasting corrosion protection to metal surfaces. However, it also produces zinc fumes and acidic vapors that pose significant risks to worker health and facility safety. Therefore, implementing an effective ventilation and filtration system is not only a legal requirement but a critical component of sustainable production.

Zinc Fumes

At temperatures above 450°C in the galvanizing bath, zinc begins to vaporize. Upon contact with air, it rapidly oxidizes, forming zinc oxide fumes. These fumes are often invisible to the naked eye but:

Contain submicron particles that easily penetrate the respiratory system.

Can cause Metal Fume Fever, which presents flu-like symptoms such as fever, headache, muscle aches, and fatigue.

Prolonged exposure may lead to impaired lung function and chronic respiratory illnesses.

Can irritate the eyes, nose, and throat.

Acid Vapors (HCl & Flux-Related Gases)

During the pre-treatment stage of galvanizing, hydrochloric acid (HCl) and flux materials are used to prepare metal surfaces. Especially during the heating and drying steps, these chemicals release harmful vapors:

Inhaled HCl vapor can irritate and damage lung tissue.

Ammonium chloride-based fluxes release ammonia (NH₃) and chloride gases when heated.

These gases are toxic to the respiratory system and contribute to long-term corrosion of equipment.

III Bomaksan Expertise is with You

At Bomaksan, we understand that the challenges posed by zinc fumes and acidic vapors vary depending on the processes, equipment configurations, and production layouts of each galvanizing facility. That’s why we offer tailored engineering solutions—whether it’s for the zinc bath, surface preparation line, or drying section—designed specifically to suit the unique needs of your plant.

Our advanced product range combines high-efficiency filtration technology with compact and modular designs, ensuring compatibility with diverse production infrastructures. From source-capture systems to centralized ventilation solutions, Bomaksan delivers effective and scalable performance that goes beyond standard approaches.

III Advantages of Bomaksan Systems

Investing in Bomaksan not only helps you control zinc fumes and acidic vapors but also ensures a safer galvanizing environment, reduced maintenance burden, and increased operational efficiency. Here are some of the key advantages that set us apart in galvanizing processes:

Better Indoor Air Quality

Bomaksan systems effectively capture and filter zinc fumes and acidic vapors at the source, significantly improving indoor air quality. This creates a healthier environment for workers, reduces harsh odors, and enhances visibility in the production area. Cleaner air helps prevent long-term respiratory issues while also boosting employee satisfaction and overall productivity.

Reduced Maintenance Requirement and Less Downtime

Zinc fumes and acidic vapors accumulating around the galvanizing line can lead to frequent equipment failures, unplanned downtimes, and recurring cleaning requirements. Over time, this contamination causes sensitive equipment to become dirty or corroded and increases safety risks due to slippery surfaces. Bomaksan’s extraction systems, specifically designed for galvanizing processes, capture and filter harmful gases and fumes directly at the source. As a result, contamination is minimized, equipment stays clean and dry, and the lifespan of critical components is extended. With reduced cleaning needs and fewer downtimes, operations run more efficiently, maintenance costs decrease, and overall productivity increases.

Compliance with Internatioal Standards

Bomaksan filtration units are manufactured in compliance with international quality and safety standards such as ISO 9001, CE, and relevant occupational health and safety directives. By reducing worker exposure and maintaining high air cleanliness levels, our solutions not only help you meet legal requirements but also enable you to exceed global standards in your operations.

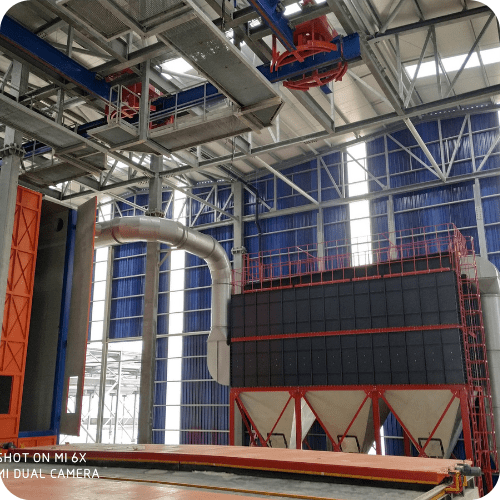

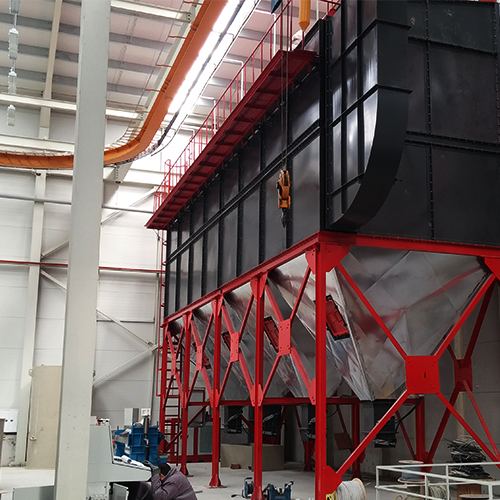

III Sample Applications

Teksin Galvaniz

Azra Galvaniz

Şara Galvaniz

KONKAP Galvaniz

III Case Studies

Are You Looking For A Solution?

Bomaksan Clean Air Experts are here for you. Fill the request form now, get one step closer to the solution

III Sample Applications

WHY BOMAKSAN?

Always With You On Your Way Of Excellence

As Bomaksan, we are aware of your desire to do your job perfectly. Excellence means both producing the best quality product, meeting the quality and deadline expectations of your customers and even exceeding them, creating a healthy and safe working environment and producing without harming the environment.

This is why your investment in Dedusting Systems and Clean Air is actually a direct investment you make to perfect your business.

- Reliable Partner With 35 Years Of Experience!

- ECO-Friendly Engineering Solutions.

- Solutions For Safe Working Environments

- Durable & Sustainable Solutions

Consult Our Clean Air Experts For A More Perfect Production Experience

You can leave your contact information for our Clean Air Experts to provide you with the best support.

You can leave your contact information for our Clean Air Experts to provide you with the best support.

We will try to answer you as soon as possible. In some cases, the response time may be 48 hours.

Bomaksan Dust Collection. It is an expert brand that has entered the production of Gas Treatment and Filtration devices and has managed to make a name for itself in the sector in a short time.

E-Newsletter Subscription

© 2017 - 2022 Bomaksan Industrial Air Filtration Systems. All Rights Reserved.