At Bomaksan, we understand that safety risks related to combustible and explosive dust vary significantly depending on the type of material used, the process structure, and the physical layout of the facility. That’s why we offer customized Ex-Proof Dust Collector and filtration systems designed in compliance with ATEX standards—whether you’re working with organic combustible dust like flour, starch, or sugar, or handling metallic or chemical powders.

Menu

Close

EX-Proof Applications

> Applications > Ex-Proof Applications

III Filtration of Combustible and Explosive Dust with Ex-Proof Dust Collectors

In production processes where combustible and explosive dust is generated, transporting, processing, or collecting this dust poses serious risks. When suspended in air at the right concentration, combustible dust can ignite or explode if exposed to a spark or hot surface. These particles also endanger worker health, damage equipment, and compromise production safety. That’s why implementing a properly designed Ex-Proof Dust Collector and filtration system is critically important.

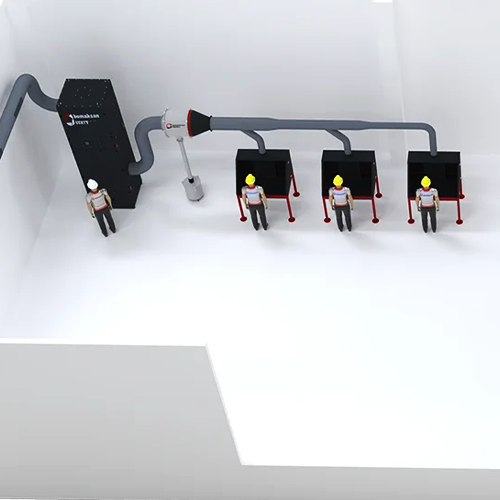

In applications where combustible and explosive dust is released, maintaining a safe working environment requires effective and reliable combustible dust collection—it is not optional, but essential.

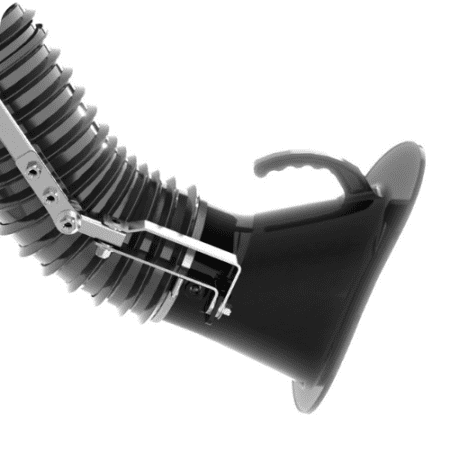

Fine combustible dust emitted from silos, bunkers, screens, crushers, conveyors, and transfer points—as well as from grinding, polishing, and cutting processes—can mix with air and form explosive atmospheres. Even a small spark or static discharge can trigger severe fires or dust explosions. Without proper and secure extraction and filtration systems, this dust can accumulate inside equipment and pose serious health and safety risks.

Although the explosiveness of dust depends on its chemical composition and particle size, industries such as food, metal, plastic, chemical, and pharmaceutical are particularly vulnerable. The risk is even greater in enclosed or poorly ventilated environments.

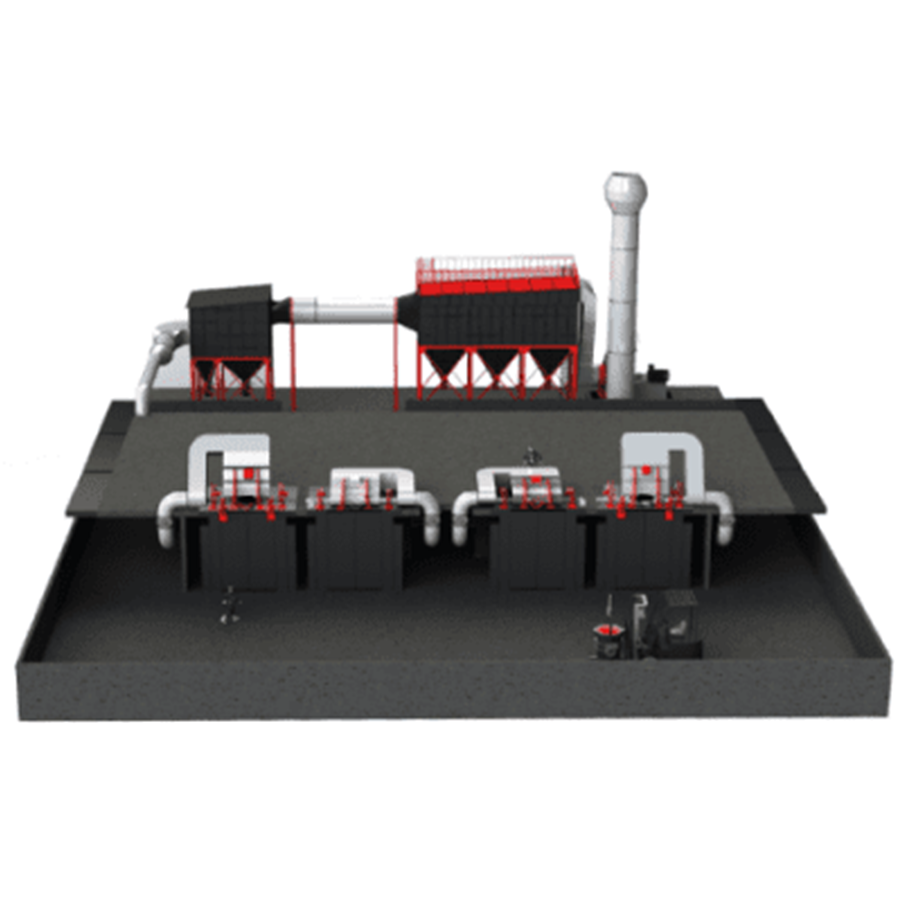

Industrial Ex-Proof Dust Collectors used in explosive dust areas must be designed in compliance with international standards such as ATEX and NFPA. The type, quantity, particle size, and density of the dust generated by the process play a critical role in defining the system design. Additionally, the characteristics of the installation area and the defined ATEX ZONE classification are key factors in selecting the appropriate equipment for the dust collection unit.

III What is ATEX Directives?

Safety in Explosive Atmospheres

In industrial environments where combustible gases, vapors, and combustible dust are present, ensuring workplace safety is essential. To address these risks, the European Union has adopted two directives known as the ATEX Directives, which regulate explosive atmospheres and combustible dust hazards:

These directives aim to guarantee the safety of equipment and protective systems used in explosive atmospheres. ATEX-compliant products help protect both personnel and facility infrastructure.

Standards for Equipment and System Selection

The ATEX Directive classifies equipment into categories based on their suitability for use in explosive zones and defines specific technical requirements for each. From electric motors to Ex-Proof Dust Collectors, all equipment operating in combustible dust environments must comply with these standards. Improper equipment selection may lead to severe safety risks and legal liabilities.

Legal Compliance and Responsibility

For industrial facilities handling combustible dust, ATEX compliance is not optional—it is mandatory. Meeting these regulations is critical not only for passing inspections, but also for protecting employee safety and ensuring uninterrupted operations. Choosing certified Combustible Dust Collection systems is a vital step toward maintaining a compliant and secure working environment.

III Bomaksan Expertise is with You

III Advantages of Bomaksan Systems

Investing in Bomaksan not only helps you control combustible dust in high-risk processes such as conveying, screening, packaging, cutting, polishing, and grinding, but also ensures a safer production environment, longer equipment lifespan, and uninterrupted operations. Here are some key advantages that make Bomaksan stand out in combustible dust collection applications:

Better Indoor Air Quality

Bomaksan systems capture and filter fine combustible dust particles directly at the source in processes where explosive dust is generated. This significantly reduces explosion risks and improves air quality in facilities processing high-risk materials such as flour, starch, and metal dust. As a result, the working environment becomes both safer and healthier—dust cloud formation is prevented, visibility is improved, and operational control is maintained.

Reduced Maintenance Requirement and Less Downtime

In production environments, combustible dust generated during crushing, grinding, screening, mixing, cutting, polishing, and sanding can quickly accumulate. This buildup increases the risk of equipment failures, unplanned downtimes, and potentially explosive atmospheres. Over time, fine, abrasive, and conductive dust can penetrate sensitive components, causing corrosion, short circuits, and permanent damage—especially in automation systems and electrical control panels.

Bomaksan’s Ex-Proof Dust Collector systems are specifically designed for combustible dust hazards. By safely capturing dangerous particles at the source, they minimize contamination and dust accumulation. As a result, equipment stays cleaner and lasts longer, while production lines run more safely and without interruption.

Compliance with Internatioal Standards

Bomaksan filtration units are designed and manufactured in compliance with ISO 9001, CE, ATEX, and relevant occupational health and safety directives. In environments with combustible dust risks, we prioritize safety by offering products fully compliant with the ATEX Directive 2014/34/EU. By reducing worker exposure and maintaining high air cleanliness, our Ex-Proof Dust Collector solutions not only help you meet legal requirements but also enable you to exceed global standards in combustible dust collection and workplace safety.

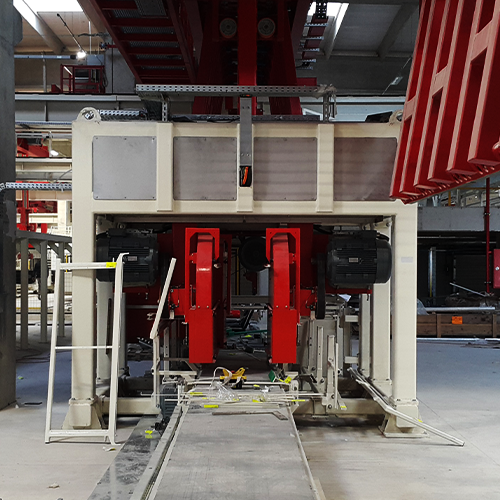

III Example Applications

III Related Products

Are You Looking For A Solution?

Bomaksan Clean Air Experts are here for you. Fill the request form now, get one step closer to the solution.

WHY BOMAKSAN?

Always With You On Your Way Of Excellence

As Bomaksan, we are aware of your desire to do your job perfectly. Excellence means both producing the best quality product, meeting the quality and deadline expectations of your customers and even exceeding them, creating a healthy and safe working environment and producing without harming the environment.

This is why your investment in Dedusting Systems and Clean Air is actually a direct investment you make to perfect your business.

- Reliable Partner With 35 Years Of Experience!

- ECO-Friendly Engineering Solutions.

- Solutions For Safe Working Environments

- Durable & Sustainable Solutions

Consult Our Clean Air Experts For A More Perfect Production Experience

You can leave your contact information for our Clean Air Experts to provide you with the best support.

You can leave your contact information for our Clean Air Experts to provide you with the best support.

We will try to answer you as soon as possible. In some cases, the response time may be 48 hours.

Bomaksan Dust Collection. It is an expert brand that has entered the production of Gas Treatment and Filtration devices and has managed to make a name for itself in the sector in a short time.

E-Newsletter Subscription

© 2017 - 2022 Bomaksan Industrial Air Filtration Systems. All Rights Reserved.