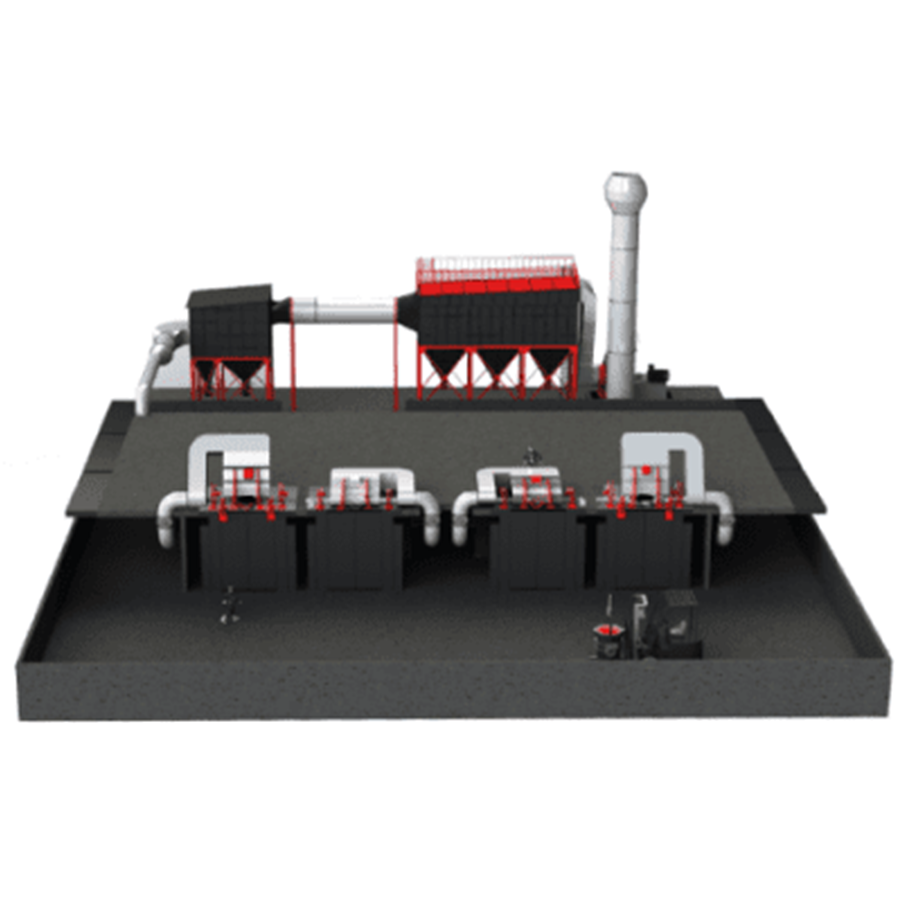

In die casting processes, mold release agents used often contain chemicals that, upon contact with molten metal, generate dense and oily fumes. When these fumes are filtered using conventional dry filters or standard oil mist filters, the filter pores clog quickly, significantly reducing system performance and increasing the risk of fire. Clogged filters also lead to frequent maintenance, longer downtimes, and high replacement costs.

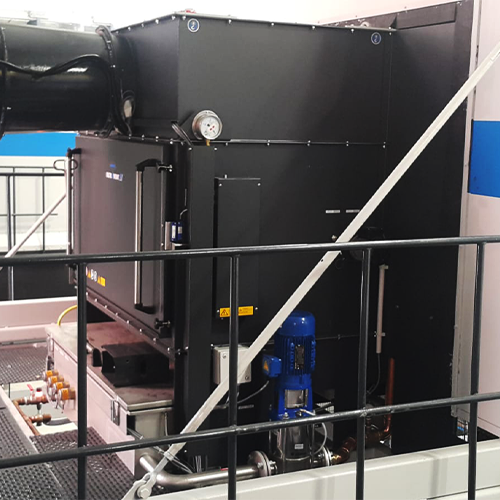

At Bomaksan, we offer a safer, more efficient, and long-lasting filtration solution through our partnership with German-based KMA, a leading manufacturer of electrostatic filters with automatic washing functionality. These advanced systems ensure uninterrupted production with minimal maintenance, while maximizing ventilation efficiency. Washable electrostatic filter technology not only improves indoor air quality but also reduces maintenance expenses, accelerating return on investment. You protect both the health of your employees and your surrounding environment while safeguarding production efficiency.