Menu

Close

Foundry Case Studies

Dust Collection and Filtration Solutions That May Interest You

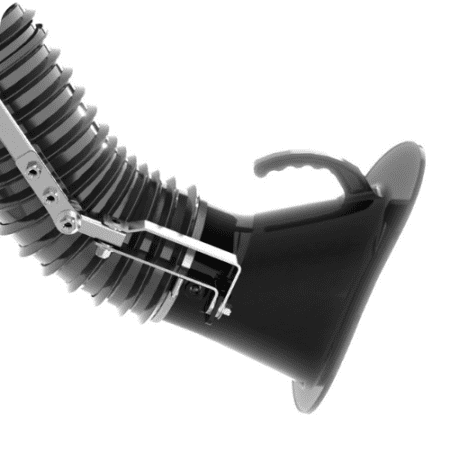

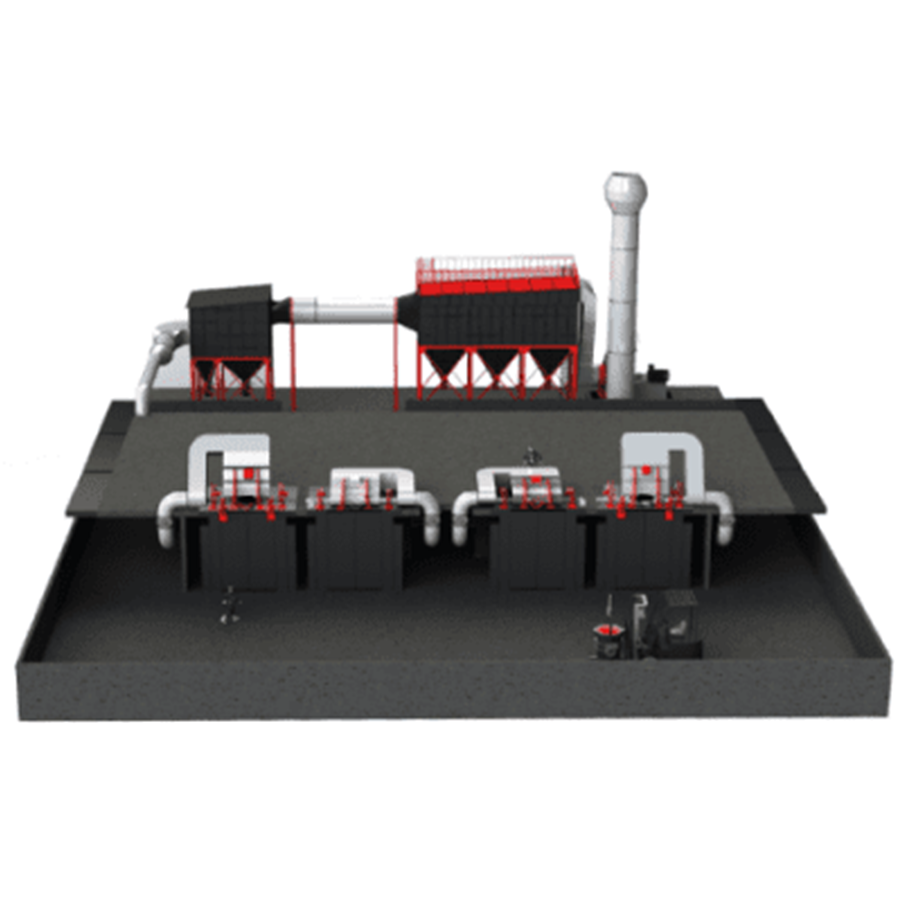

Each industry, process, and company faces unique challenges—and the complexity of solving them varies accordingly. At Bomaksan, we recognize these distinct needs and develop custom dust collection, fume extraction, and air filtration solutions tailored to each client. In this section, you can explore some of the projects we’ve developed for various industries.

Silvan - Foundry

Silvan Döküm collaborated closely with Bomaksan's engineers on a comprehensive dust collection and filtration project covering all stages of its foundry processes.

MES - Foundry

To address the fire incident in its melting furnaces caused by an outdated filtration system, MES Döküm installed a new and reliable fume extraction solution from Bomaksan.

Bomaksan Dust Collection. It is an expert brand that has entered the production of Gas Treatment and Filtration devices and has managed to make a name for itself in the sector in a short time.

E-Newsletter Subscription

© 2017 - 2022 Bomaksan Industrial Air Filtration Systems. All Rights Reserved.