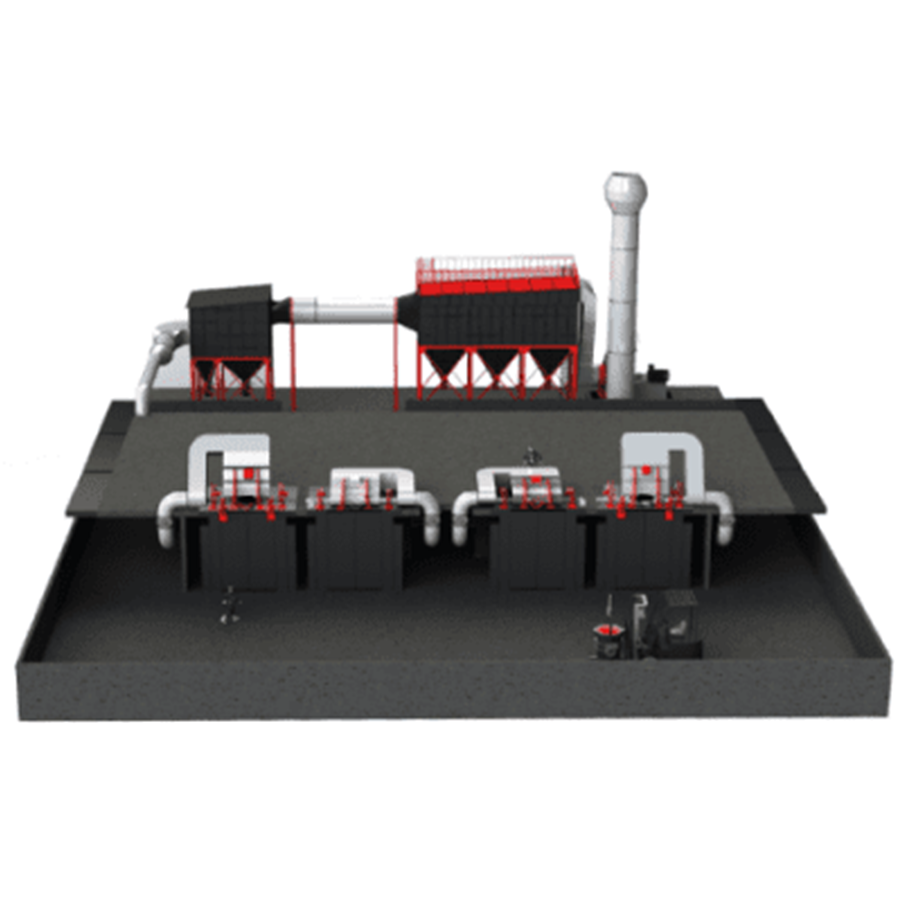

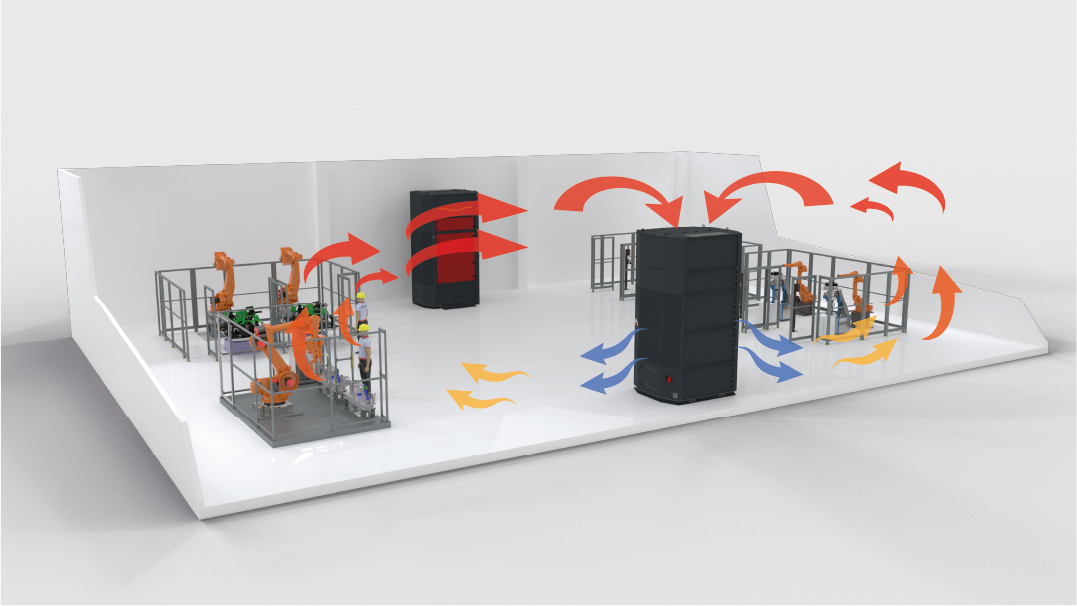

ALVERpro air towers by Bomaksan are high-efficiency air filtration systems designed in line with the layered ventilation principle recommended by industry associations and international standards. These systems draw contaminated and hot air from the upper area of the facility, purify it through advanced filtration technology, and then release clean air back into the environment from a point close to the floor. This process ensures both uniform air distribution and improved air quality and comfort for employees. Recirculating the purified air within the system provides businesses with a significant energy efficiency advantage by delivering up to 70% savings in heating costs, especially during cold seasons. The ALVERpro series is an ideal and long-lasting solution for all industrial facilities aiming to improve indoor air quality and establish sustainable production conditions.

Menu

Close

ALVER Series

III Tanıtım Videosu

Get A Product Quote

Send us your information immediately with the product request form, and our sales team will reach you as soon as possible.

III ALVER Series – Air Cleaning Tower

Efficient Air Filtration Where Source Extraction Is Not Feasible

ALVER series air towers by Bomaksan are engineered for use in industrial environments where source extraction is not possible or insufficient. These high-performance air filtration units effectively clean ambient air by removing dust, fumes, and particles that accumulate in large production areas, ensuring a safer and healthier workspace.

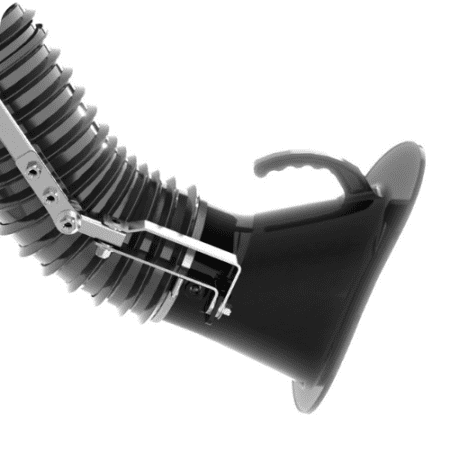

Automatic Filter Cleaning System for Low Maintenance

Each ALVER air tower is equipped with an advanced jet-pulse cleaning system that uses compressed air to automatically clean the filter elements inside the unit. This self-cleaning mechanism

Extends filter life

Reduces maintenance frequency

Significantly lowers filter replacement costs

Bu özellik, uzun vadeli ve ekonomik hava filtreleme çözümleri arayan işletmeler için büyük avantaj sağlar.

Energy-Efficient Fans with

High Suction Performance

The ALVER series offers high-efficiency fan options to meet various industrial needs. Radial Fans with Frequency Converters for adjustable airflow control. In this way:

Provide strong suction power

Consume less energy

Emmit low noise level

This features making ALVER Series ideal for indoor use without disrupting operators or surrounding workstations.

Touchscreen Control Panel with

Smart Scheduling Mode

All ALVER units come standard with a 7-inch LCD touchscreen panel that simplifies operation and enhances user interaction. Integrated with an intelligent Scheduling Mode, this system automates the daily start-stop routines.

With scheduling mode:

You only need to set break and shut-off times once

The PLC-based control unit manages all operations automatically

Jet-pulse filter cleaning is scheduled during breaks to avoid noise disruption during active work hours

This not only ensures continuous air quality management but also improves operator comfort and workflow efficiency

REDUCE YOUR HEATING COSTS

WITH ALVER CLEAN AIR TOWER

III Catalogs

WHY BOMAKSAN?

Always With You On Your Way Of Excellence

As Bomaksan, we are aware of your desire to do your job perfectly. Excellence means both producing the best quality product, meeting the quality and deadline expectations of your customers and even exceeding them, creating a healthy and safe working environment and producing without harming the environment.

This is why your investment in Dedusting Systems and Clean Air is actually a direct investment you make to perfect your business.

- Reliable Partner With 35 Years Of Experience!

- ECO-Friendly Engineering Solutions.

- Solutions For Safe Working Environments

- Durable & Sustainable Solutions

Consult Our Clean Air Experts For A More Perfect Production Experience

You can leave your contact information for our Clean Air Experts to provide you with the best support.

You can leave your contact information for our Clean Air Experts to provide you with the best support.

We will try to answer you as soon as possible. In some cases, the response time may be 48 hours.

Bomaksan Dust Collection. It is an expert brand that has entered the production of Gas Treatment and Filtration devices and has managed to make a name for itself in the sector in a short time.

E-Newsletter Subscription

© 2017 - 2022 Bomaksan Industrial Air Filtration Systems. All Rights Reserved.