Menu

Close

Building Materials

> Applications > Building Materials

III Dust Collection Systems in Building Materials Industry

Building materials manufacturing (such as concrete, gypsum, cement, and insulation production) generates high volumes of fine and hazardous dust. These airborne particles not only compromise worker health and safety but also contaminate production lines, damage sensitive equipment, and create fire or explosion risks.

To ensure a safe and efficient working environment in the building materials industry, effective dust control is not just a recommendation—it’s a necessity.

Key dust sources such as cement silos, grinding mills, cutting tables, material conveyors, and packaging lines continuously release fine particles into the air. Without proper extraction systems, this dust settles on machinery, seeps into electrical panels, and enters workers’ lungs—posing both operational and health hazards.

In particular, silica dust from concrete and cutting operations is known to cause long-term respiratory illnesses such as silicosis. Additionally, gypsum and wood-based dust can be highly combustible, increasing the risk of fire or explosion in poorly ventilated spaces.

Implementing an industrial-grade dust collection system minimizes these risks, extends equipment lifespan, reduces cleaning frequency, and ensures compliance with workplace safety standards such as OSHA and ATEX.

Why Clean Air?

In the building materials industry, clean air is not a luxury—it’s a fundamental requirement for safeguarding worker health, ensuring consistent production performance, protecting sensitive equipment from premature failure, and securing the long-term success and sustainability of industrial operations.

III Why Need Dust Collection?

Health & Safety First

Clean air is critical for protecting workers from harmful airborne particles such as silica, cement dust, and fine particulates generated during mixing, cutting, and packaging processes. Prolonged exposure can lead to serious health conditions, including respiratory diseases, chronic fatigue, and even cancer

Equipment Efficiency

Dust accumulation on machinery and control panels causes overheating, breakdowns, and costly maintenance. Clean air reduces downtime, prevents system failures, and extends the lifespan of production equipment.

Regulatory Compliance

Occupational safety authorities like OSHA and international standards such as ATEX mandate strict dust control in industrial environments. Maintaining clean air helps facilities stay compliant, avoid penalties, and build a responsible, sustainable operation.

The Hidden Dangers of Silica and Quartz Dust

Silica dust, especially in its crystalline form known as quartz dust, is one of the most hazardous airborne contaminants found in industries such as construction, building materials manufacturing, mining, and stone cutting. When materials like concrete, brick, or stone are cut, ground, or drilled, they release respirable crystalline silica (RCS)—ultra-fine particles that can deeply penetrate the lungs.

Health Risks of Silica Exposure

Long-term exposure to silica dust can lead to severe and irreversible diseases, including:

Silicosis – a progressive and incurable lung disease

Lung cancer – classified as a Group 1 carcinogen by the WHO

Chronic Obstructive Pulmonary Disease (COPD)

Kidney disease and autoimmune disorders

Even short-term overexposure can cause respiratory distress, eye irritation, and skin problems. Workers are often unaware of the danger because quartz dust is microscopic and invisible to the naked eye.

III Bomaksan Expertise is with You

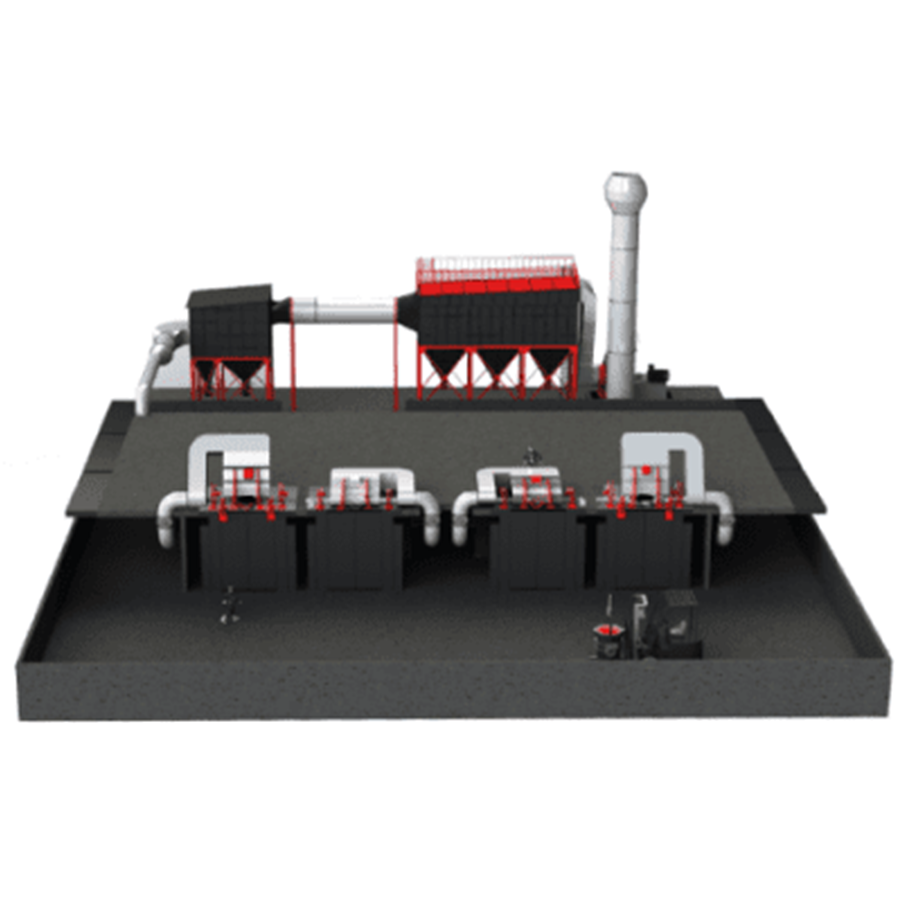

At Bomaksan, we recognize that dust-related challenges in the building materials industry—such as those caused by silica, quartz, cement, and gypsum dust—differ widely depending on the raw materials used, the processes involved, and the layout of each production facility. That’s why we design customized extraction and filtration systems specifically tailored to your operation—whether it’s concrete batching, gypsum board cutting, or cement bagging.

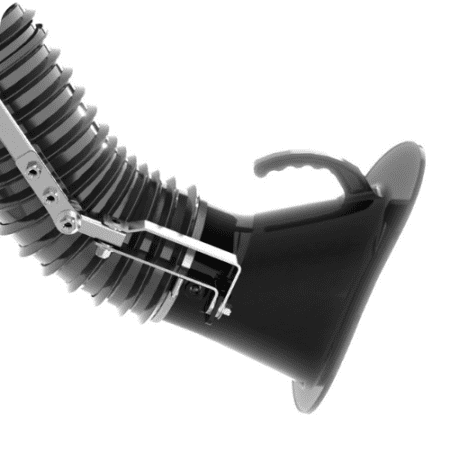

Our product range features high-efficiency filtration technologies engineered to meet the demanding requirements of heavy dust loads, while offering compact, modular, and energy-efficient designs. From point-of-source extraction units to centralized dust collection systems with ATEX-compliant features, Bomaksan ensures clean air, reliable performance, and regulatory compliance—so your operations stay productive, safe, and sustainable.

III Advantages of Bomaksan Systems

Investing in Bomaksan not only helps you control harmful silica and quartz dust in building materials production, but also ensures a safer working environment, extended equipment life, and improved production efficiency. Here are some of the key advantages that set us apart in dust collection solutions for the construction materials industry:

Better Indoor Air Quality

Bomaksan systems effectively capture and filter silica, quartz, and cement dust directly at the source, significantly improving indoor air quality in building materials production facilities. This leads to a healthier and safer environment for workers, minimizes airborne contamination, and maintains clear visibility across production areas. Cleaner air not only helps prevent long-term respiratory illnesses such as silicosis, but also reduces equipment wear and downtime—ultimately increasing employee satisfaction, compliance, and operational productivity.

Reduced Maintenance Requirement and Less Downtime

Dust from materials like cement, gypsum, and concrete can accumulate rapidly around cutting, grinding, and mixing stations, leading to frequent equipment malfunctions, unplanned downtimes, and constant cleaning cycles. Over time, this fine and abrasive dust contaminates sensitive components, clogs filters, and causes corrosion—especially in electrical enclosures and automation systems. Bomaksan’s dust extraction systems, engineered specifically for building materials production, capture harmful particles directly at the source. As a result, contamination is drastically reduced, equipment remains cleaner and more reliable, and the lifespan of critical systems is extended. With less dust settling on surfaces, facilities benefit from smoother operations, lower maintenance costs, and increased overall productivity.

Compliance with Internatioal Standards

Bomaksan filtration units are manufactured in compliance with international quality and safety standards such as ISO 9001, CE, and relevant occupational health and safety directives. By reducing worker exposure and maintaining high air cleanliness levels, our solutions not only help you meet legal requirements but also enable you to exceed global standards in your operations.

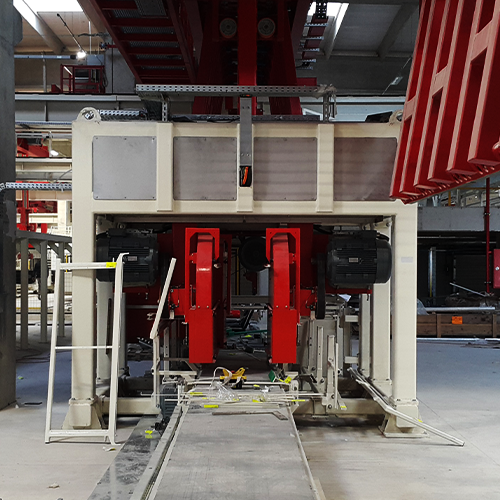

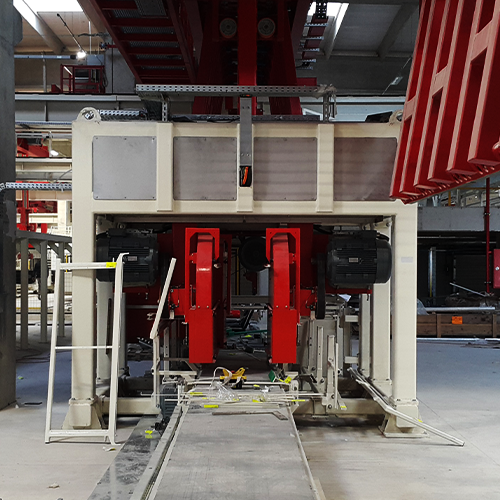

III Example Applications

III Related Products

III Case Studies

Are You Looking For A Solution?

Bomaksan Clean Air Experts are here for you. Fill the request form now, get one step closer to the solution.

WHY BOMAKSAN?

Always With You On Your Way Of Excellence

As Bomaksan, we are aware of your desire to do your job perfectly. Excellence means both producing the best quality product, meeting the quality and deadline expectations of your customers and even exceeding them, creating a healthy and safe working environment and producing without harming the environment.

This is why your investment in Dedusting Systems and Clean Air is actually a direct investment you make to perfect your business.

- Reliable Partner With 35 Years Of Experience!

- ECO-Friendly Engineering Solutions.

- Solutions For Safe Working Environments

- Durable & Sustainable Solutions

Consult Our Clean Air Experts For A More Perfect Production Experience

You can leave your contact information for our Clean Air Experts to provide you with the best support.

You can leave your contact information for our Clean Air Experts to provide you with the best support.

We will try to answer you as soon as possible. In some cases, the response time may be 48 hours.

Bomaksan Dust Collection. It is an expert brand that has entered the production of Gas Treatment and Filtration devices and has managed to make a name for itself in the sector in a short time.

E-Newsletter Subscription

© 2017 - 2022 Bomaksan Industrial Air Filtration Systems. All Rights Reserved.